What is 430 stainless steel?

What is 430 stainless steel? Its composition, properties, and applications

430 stainless steel is a ferritic stainless steel alloy with poor corrosion resistance and resistance to nitric acid corrosion, making it useful for chemical applications. Its corrosion resistance is not as good as stainless steels 304 and 316. Alloy 430 benefits from good formability and can be easily welded, though it is not suitable for severe corrosion applications. 430 stainless steel is commonly used in manufacturing household appliances and automotive parts for decorative purposes.

Related Products:

430 Stainless Steel Coil Stainless Steel Strip 430 Stainless Steel Sheet Seamless Stainless Steel Pipe Stainless Steel Welded Pipe Stainless Steel Angle Stainless Steel Flat Bar Stainless Steel Round Bars Hairline Stainless Steel Sheet Decorative Stainless Steel Pipes Stainless Steel Circle

What is 430 Stainless Steel?

430 stainless steel is stainless steel with an alloy composition of 18% chromium and 0% nickel, a popular choice for creating safe, high-quality products that offer high aesthetic appeal and enhanced professionalism. 430 stainless steel has a high chromium content and no nickel, providing excellent rust resistance in various harsh environments. 430 stainless steel has improved strength and better bending properties at high temperatures, retaining excellent mechanical properties and corrosion resistance at low temperatures.

Classification of 430 Stainless Steel by Composition

430 stainless steel is divided into two main types for identification and appropriate application in production: 430 stainless steel and 430F stainless steel. Additionally, a variant, 434 stainless steel, improves corrosion resistance by adding molybdenum.

Standard 430 Stainless Steel

The standard 430 stainless steel consists of Fe, Cr, Mn, Si, P, and S components. However, aside from chromium and iron, all other elements are present in very low, insignificant amounts. When 430 stainless steel is well-polished, it enhances surface corrosion resistance and oxidation resistance against some weak acids.

430F Stainless Steel

430F stainless steel is also a common version of 430 stainless steel, mainly available in bar and block forms. However, the wear resistance of grooves and holes in 430F stainless steel is not very good, much lower than other types in the group. This is due to the removal of the sulfur element from its composition.

Classification of 430 Stainless Steel by Surface Finish

The classification by surface finish of 430 stainless steel is based on the degree of surface polishing. Depending on the level of gloss and the polishing process, there are different types available in the market. Below are four typical surface finishes based on gloss:

-

BA Surface

430 stainless steel BA surface is a high-quality finish with a high shine, comparable to mirror-like gloss. This 430 stainless steel BA material is cold-rolled and bright-annealed, suitable for electrical equipment and household appliances. -

2B Surface

Unlike the BA finish, 430 stainless steel 2B has a matte milk color with good shine and flatness. 430 stainless steel 2B is widely used in various fields, including medical equipment, construction materials, and the food industry. -

HL Surface

430 stainless steel HL surface can be mechanically polished with sandpaper, giving it a relatively glossy finish with continuous minor scratches. This 430 stainless steel HL is commonly used in elevator decoration, interior and exterior design, or construction. -

No.1 Surface

The 430 stainless steel No.1 surface undergoes very careful processing, including hot rolling and thermal treatment according to process standards. 430 stainless steel No.1 is mainly used in the production of industrial machinery, tanks, beer-wine containers, or chemicals.

Properties of 430 Stainless Steel

430 stainless steel is widely used today because it has perfect mechanical and physical properties. Its strength is quite high, which is a major advantage of 430 stainless steel. One of its standout features is that it is very safe for human health and environmentally friendly due to its oxidation resistance. Moreover, 430 stainless steel is easy to fabricate, heat-resistant, and cost-effective.

-

Corrosion Resistance

430 stainless steel is a ferritic stainless steel with chromium content and is non-hardened, combining good corrosion resistance with shaping properties and useful mechanical characteristics. Its resistance to nitric acid corrosion makes it suitable for certain chemical applications. Specifically, decorative parts and automotive components represent the largest application areas for 430 stainless steel. -

Good Oxidation Resistance

430 stainless steel has good corrosion resistance combined with excellent formability. It is very similar to stainless steel grade 439 with slightly lower chromium content at a minimum of 16%. However, 430 stainless steel has better oxidation and corrosion resistance than grade 409. 430 stainless steel is commonly used in indoor environments. -

Easy to Fabricate

430 stainless steel is highly easy to fabricate, with high chromium content and no nickel, which increases its mechanical strength and tensile strength. 430 stainless steel material can be processed into various shapes such as bending, cutting, welding, and used to produce many decorative parts. It can be easily shaped cold through bending, drawing, and welding. -

Good Heat Resistance

With high chromium content beneficial for resistance, corrosion resistance, and oxidation resistance at temperatures up to 870°C, 430 stainless steel has a melting temperature range from 400°C to 600°C. For this reason, it is used in high-temperature environments. -

Cost-Effective

With many outstanding advantages such as high heat resistance, easy fabrication, and processing, 430 stainless steel is chosen by many customers because it is extremely cost-effective while still delivering satisfactory results. The price of 430 stainless steel is about three-quarters of 201 stainless steel and half of 304 stainless steel.

Chemical Composition of 430 Stainless Steel

The structure of 430 stainless steel is primarily based on the chemical composition with varying content. Since it is divided into two main types, 430 stainless steel and 430F stainless steel, the composition in these two types differs. However, they are similar in main components, with the biggest difference being the sulfur content. Below is a detailed table of the chemical element content in 430 stainless steel’s composition.

| Element | 430 Stainless Steel | 430F Stainless Steel |

|---|---|---|

| % Carbon | 0-0.12 | 0-0.12 |

| % Manganese | 0-1 | 0-1.25 |

| % Phosphorus | 0-0.04 | 0-0.06 |

| % Sulfur | 0-0.03 | 0.15 |

| % Silicon | 0-1 | 0-1 |

| % Chromium | 16-18 | 16-18 |

| % Nickel | 0-0.5 | 0 |

Mechanical Properties of 430 Stainless Steel

430 stainless steel has relatively low tensile strength. The key highlight in its mechanical properties is its ease of bending and shaping with an average ductility rate. Below are the mechanical properties of 430 stainless steel:

-

Tensile Strength: 484 MPa/min

-

Shear Stress: 310 MPa

-

Elongation (A50): 22 mm

-

Hardness (HBW): 183

Physical Properties of 430 Stainless Steel

One of the main reasons 430 stainless steel is widely used in household production is its excellent heat resistance. Specifically, it can withstand temperatures up to 870°C and continuously up to 815°C. Below are the prominent physical properties of 430 stainless steel:

-

Density (g/cm³): 7.8

-

Melting Point (°C): 1425-1510

-

Specific Heat (J/kg·°C): 460 from 0-100°C

-

Electrical Resistivity (μΩ·m) (20°C): 0.6

-

Permeability of 430 Stainless Steel: 600-1100

-

Elastic Modulus (GPa): 200 (10⁶ psi)

-

Thermal Diffusivity (mm²/s): 7.3

-

Thermal Conductivity (W/m·K): 26.1 at 100°C and 26.3 at 500°C

Quality Standards for 430 Stainless Steel

As with other materials used in manufacturing, 430 stainless steel must meet certain standards. These standards relate to technical properties, practices, and classification for materials. 430 stainless steel complies with the ASTM A240/A240M standards for its attributes. There are three forms of 430 stainless steel products that are produced in accordance with these standards:

-

430 Stainless Steel (JIS Standard): Japanese Industrial Standard.

-

430 Stainless Steel (ASTM Standard): American Society for Testing and Materials.

-

430 Stainless Steel (AISI Standard): American Iron and Steel Institute.

Common 430 Stainless Steel Products in the Market

Although 430 stainless steel has lower strength compared to other types, its cost-effectiveness is a significant advantage. As an alloyed material, 430 stainless steel is widely used in both industrial and household sectors, with easily replaceable products. Below are some common 430 stainless steel products in the market today:

-

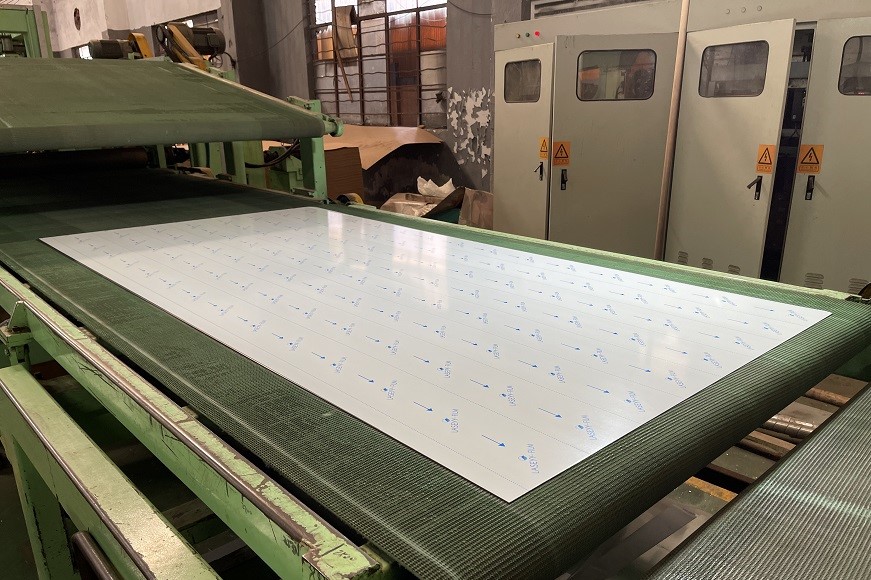

430 Stainless Steel Sheets

-

430 Stainless Steel Coils

-

430 Stainless Steel Tubes

-

430 Stainless Steel Strapping

-

430 Stainless Steel Bars

-

430 Stainless Steel Wires

Applications of 430 Stainless Steel

430 stainless steel, with its chromium and iron composition belonging to the ferritic group, is highly suitable for producing many useful items due to its corrosion resistance, resistance to environmental impacts, and excellent formability. With its high load-bearing capacity, durability, and resistance to breakage or cracking at welded joints, 430 stainless steel is widely used in various industries, including:

-

Automotive Manufacturing

-

Transportation Industry

-

Energy and Chemical Processing Industries

-

Food and Beverage

-

Household Appliances and Catering Services

-

Telecommunications

-

Interior Decoration and Construction

Identifying 430 Stainless Steel

It is difficult to differentiate between various types of stainless steel with the naked eye. Most people can distinguish between alloys such as iron, aluminum, and stainless steel. However, to clearly identify whether it is 430 stainless steel or another type like 201 or 304, certain techniques or knowledge are required.

Identifying 430 Stainless Steel with a Magnet

Why use a magnet to identify 430 stainless steel? The characteristic of this material is its magnetic property, so it will be attracted to a magnet. This is a simple and effective method that can be actively performed. This property is a key difference from 304 stainless steel, which has very weak magnetic attraction. Using a magnet is the quickest way to distinguish between these two types of stainless steel.

Identifying 430 Stainless Steel with Sparks when Cutting

This method requires the appropriate tools or conditions, so it can only be used in a production setting. When using this method, the difference between 430 stainless steel and 304 is fairly obvious, but it can be difficult to distinguish 430 stainless steel from 201 stainless steel. If sparks appear as large yellow bursts, it is likely 430 stainless steel.

Identifying 430 Stainless Steel with Acid

Compared to the methods above, using acid is the most accurate method. For this, prepare concentrated hydrochloric acid (HCl) or sulfuric acid (H₂SO₄). Drop the acid onto the 430 stainless steel surface, and it will corrode quickly. The distinguishing feature is the bubbling effect and the appearance of a brick-red color on the surface in contact with the acid.

Common Issues Related to 430 Stainless Steel

There are many concerns when purchasing and using 430 stainless steel. Customers often face challenges in understanding its properties. Information available on the internet can be overly general and sometimes unclear. Below are some frequently raised issues related to 430 stainless steel.

Which is Better: 430 Stainless Steel or 304 Stainless Steel?

304 stainless steel is among the top stainless steel types. When comparing 430 stainless steel to 304 stainless steel in detail, 304 outperforms 430 in nearly every way. While 430 stainless steel has limitations in many aspects, 304 stainless steel is almost flawless, with high ductility, excellent oxidation resistance, and is particularly rust-resistant. However, depending on the application, 430 stainless steel is more cost-effective and flexible.

What is the Difference Between 430 and 201 Stainless Steel?

Both 430 and 201 stainless steels are mid-range options primarily used for household purposes. However, there is a difference in quality and cost. 430 stainless steel has lower durability, corrosion resistance, and oxidation resistance compared to 201. Therefore, products made from 430 stainless steel are typically cheaper.

What is the Difference Between 430 and 304 Stainless Steel?

There are many differences between 430 and 304 stainless steel. While 304 stainless steel has exceptional strength and resistance properties, 430 stainless steel lags significantly behind, being classified as mid-range and having many limitations in terms of quality. In terms of chemical composition, 304 stainless steel contains 10% nickel, whereas 430 contains no nickel. Products made from 304 stainless steel are more expensive, often double the price of those made from 430.

Is 430 Stainless Steel Cookware Safe?

Stainless steel cookware is common, but 430 stainless steel is more prone to oxidation, so it may react with compounds in food when cooking. The durability of 430 stainless steel is low, and it may flake off over time. If used for extended periods, this type of cookware can become hazardous when cooking certain foods. However, due to its low cost, 430 stainless steel remains popular.

Does 430 Stainless Steel Attract Magnets?

Yes, 430 stainless steel is highly magnetic and can be attracted to magnets.

Is 430 Stainless Steel Harmful?

As mentioned, 430 stainless steel has low oxidation resistance and durability. When used in construction and manufacturing industries, it is not overly harmful. However, for consumer products used frequently with food storage, 430 stainless steel may not guarantee health safety, especially with prolonged use.

Does 430 Stainless Steel Rust?

The key difference between 430 stainless steel and other types is its very low or lack of nickel content. As a result, it has low oxidation resistance and is more prone to rusting.

Can 430 Stainless Steel Be Painted?

Stainless steel is difficult to paint, but 430 stainless steel can be painted using specialized techniques. Modern painting techniques can be applied to 430 stainless steel surfaces to reduce oxidation and rusting.

Alternative Grades to 430 Stainless Steel

-

304 Stainless Steel: One of the most popular and widely used types of stainless steel, 304 stainless steel offers excellent rust resistance and is commonly found in kitchenware.

-

201 Stainless Steel: Made from manganese, nitrogen, and a small amount of nickel, 201 stainless steel is a versatile material, often used in environments with moderate corrosion risk.

-

316 Stainless Steel: Known for its high corrosion resistance, especially in marine environments, 316 stainless steel is widely used in projects requiring superior durability and resistance to harsh chemicals.

Where to Buy Affordable 430 Stainless Steel

430 stainless steel is relatively inexpensive and offers moderate durability and corrosion resistance. Products made from this material are commonly used in consumer goods. As a direct manufacturer and original source based in China, OrinoxSteel supplies high-quality yet affordable 430 stainless steel materials. We maintain full control over production and inventory, allowing us to fulfill bulk orders efficiently and ensure fast, reliable delivery.

Contact for Pricing of 430 Stainless Steel

OrinoxSteel specializes in supplying genuine 430 stainless steel at transparent and competitive prices, complete with full documentation. As a direct manufacturer, we welcome customer inquiries through our official website, www.orinoxsteel.com. Our sales team is ready to respond quickly to your requests, provide quotes, and support you throughout the purchasing process online.