Top 10 Most Popular Stainless Steel Finishes Globally

Top 10 Popular Stainless Steel Finishes In The World

Related Products:

Hairline Stainless Steel Sheet Embossed Stainless Steel Sheet Etched Stainless Steel Sheet Water Ripple Stainless Steel Sheet

Top 1 Finish : Mirror

Mirror stainless steel is achieved through advanced grinding and polishing techniques that create an exceptionally smooth surface with high reflectivity, similar to a true mirror effect. This decorative stainless steel finish not only delivers stunning visual impact but also offers excellent durability and resistance to acids and corrosion, making it a preferred choice for both modern architectural and interior design projects.

Key Features of Mirror Stainless Steel

-

Ultra-high-definition mirror effect with brilliant reflectivity

-

Excellent acid and corrosion resistance

-

Elegant appearance combined with long-lasting durability

-

Eco-friendly, safe, and hygienic material

-

Easy to clean and maintain for long-term use

Applications of Mirror Stainless Steel

With its striking visual appeal and robust performance, mirror stainless steel is widely recognized as one of the best decorative materials for interior and exterior projects. Common applications include:

-

Decorative ceiling panels

-

Luxury wall cladding and interior features

-

Furniture decoration and custom accents

-

Elevator interiors and door panels

-

Building façades and architectural highlights

Top 2 Finish: Brushed

Brushed stainless steel is produced through a controlled grinding and polishing process that creates distinctive linear or textured patterns on the sheet surface. Depending on the technique, brushed stainless steel can achieve different decorative effects, each with its own visual style and functional benefits.

Main Types of Brushed Stainless Steel Finishes

-

Hairline Finish

Characterized by fine, continuous lines running in a single direction, this finish resembles strands of hair. Hairline stainless steel sheets provide a sleek, modern look that is both elegant and durable, making them ideal for high-end architectural and decorative applications.

-

No.4 Finish (Satin Finish)

Also known as #4 finish, this treatment creates a unidirectional satin surface through fine abrasive polishing. No.4 stainless steel sheets are one of the most popular decorative finishes, offering a balance of sophistication and practicality, widely used in elevators, kitchen equipment, and interior decoration.

-

Vibration Finish

Created by a non-directional sanding process, vibration stainless steel sheets feature a subtle swirl or random texture with soft, diffuse reflectivity. This finish is not only visually appealing but also practical, as it effectively hides fingerprints, scratches, and other minor imperfections.

-

Cross Hairline Finish

Produced by brushing stainless steel in multiple directions, this finish results in a cross-hatched texture. Cross hairline stainless steel sheets offer a unique, decorative look that adds depth and character to architectural surfaces and modern design projects.

Key Features of Brushed Stainless Steel

-

Unique textures with multiple design options

-

Excellent acid and corrosion resistance

-

Attractive appearance combined with durability

-

Eco-friendly, safe, and hygienic material

-

Easy to clean and maintain

Applications of Brushed Stainless Steel

Due to its versatility and stylish appearance, brushed stainless steel is widely used in both residential and commercial projects. Common applications include:

-

Building façades and exterior cladding

-

Elevator interiors and door panels

-

Furniture decoration and design elements

-

Kitchens and household products

-

Home appliance design

-

Tableware and cookware manufacturing

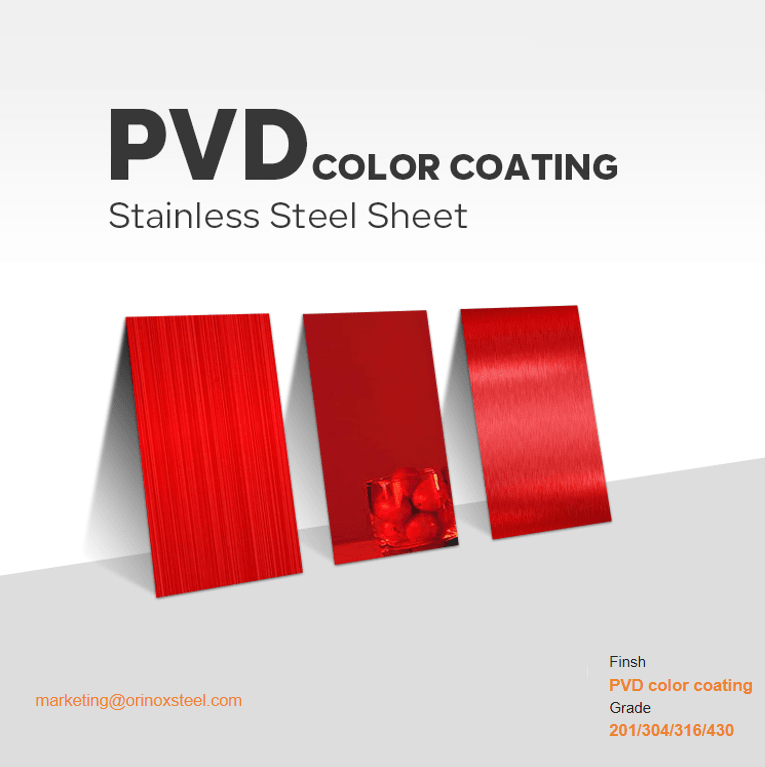

Top 3 Finish: PVD Color Coating

PVD color coating stainless steel is created through Physical Vapor Deposition (PVD), a state-of-the-art process that deposits a thin, colored layer onto the stainless steel surface. This technique combines the natural durability and corrosion resistance of stainless steel with a wide range of vibrant, long-lasting colors. PVD coatings can be applied to different finishes—including mirror, brushed, embossed, stamped, and etched stainless steel sheets—enhancing both aesthetics and functionality.

Key Features of PVD Color Coating Stainless Steel

-

Wide range of customizable colors and finishes

-

Excellent acid and corrosion resistance

-

Durable and long-lasting decorative performance

-

Eco-friendly, non-toxic, and safe

-

Even and stable color distribution

-

Resistant to fading and discoloration

-

Easy to clean and maintain

Applications of PVD Color Coating Stainless Steel

By merging high-end aesthetics with the strength of stainless steel, PVD color-coated sheets are widely used across industries where both design and performance matter:

-

Architectural projects and interior decoration

-

Modern furniture and luxury fixtures

-

Kitchen decoration and high-end cabinetry

-

Automotive trims and components

-

Premium home appliance design

-

Branding, signage, and display panels

-

Fashion accessories and jewelry manufacturing

Top 4 Finish: Embossed

Embossed stainless steel is produced by mechanically pressing a raised or recessed pattern onto the surface of a stainless steel sheet. This is typically achieved through advanced rolling or stamping techniques, where the sheet passes between rollers engraved with the desired design. The result is a distinctive textured surface that combines durability with unique decorative appeal.

Key Features of Embossed Stainless Steel

-

Distinctive metallic texture with strong visual impact

-

High rigidity and long-lasting durability

-

Excellent resistance to corrosion and rust

-

Suitable for both interior and exterior architectural applications

-

Eco-friendly, hygienic, and low maintenance

Applications of Embossed Stainless Steel

With its unique surface texture and strong performance, embossed stainless steel is widely applied in both functional and decorative projects, including:

-

Interior decoration and wall features

-

Exterior cladding and building façades

-

Elevator doors, cabins, and lobby interiors

-

Architectural and design elements

-

Industrial applications requiring durable textured finishes

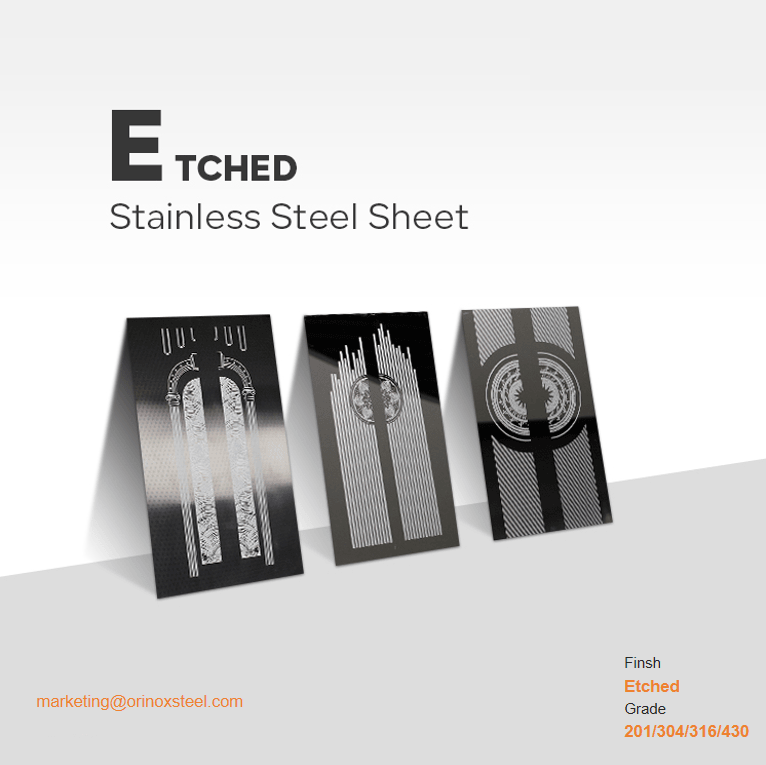

Top 5 Finish : Etched

Etched stainless steel is created through a controlled chemical or mechanical process that selectively removes material from the surface of the sheet. This technique produces intricate patterns, designs, or textures by contrasting the etched and unetched areas. The result is a decorative stainless steel finish that combines precision, durability, and aesthetic appeal, making it ideal for both functional and architectural applications.

Key Features of Etched Stainless Steel

-

Unique and customizable patterns with artistic style

-

Strong rigidity and long-lasting durability

-

Elegant decorative appeal for modern spaces

-

Excellent corrosion and rust resistance

-

Eco-friendly, safe, and easy to maintain

Applications of Etched Stainless Steel

With its diverse design possibilities, etched stainless steel is widely used in both residential and commercial projects. Common applications include:

-

Elevator interiors and decorative panels

-

Architectural wall cladding

-

Furniture accents and high-end decoration

-

Kitchen backsplashes and custom designs

-

Signage, branding, and artistic installations

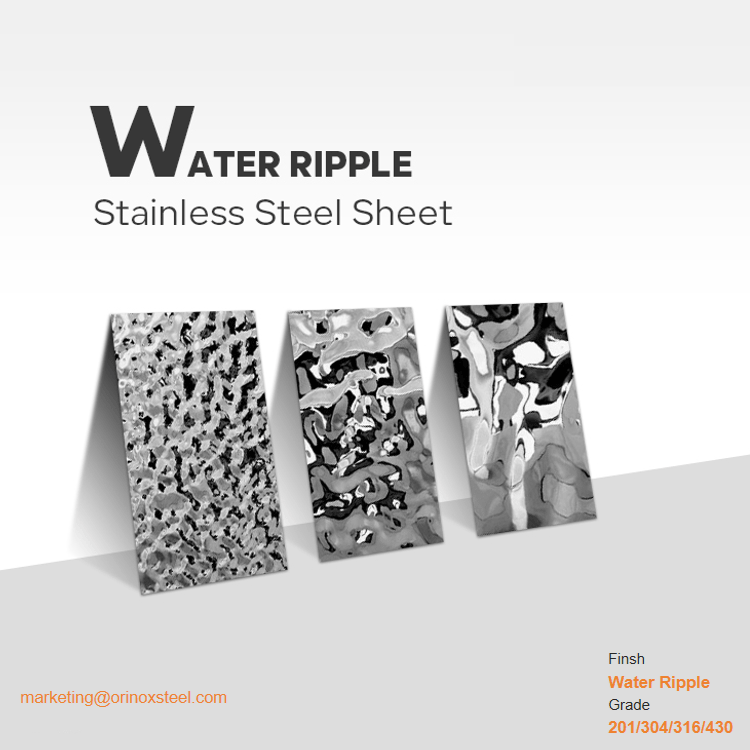

Top 6 Finish: Water Ripple

Water ripple stainless steel features a unique textured surface that resembles the natural patterns of rippling water. This distinctive finish is created through advanced processing techniques, offering both visual appeal and practical benefits. It is widely used in interior decoration, ceilings, wall panels, and high-end architectural designs, where design innovation and durability are equally important.

Key Features of Water Ripple Stainless Steel

-

Distinctive water ripple texture with strong visual impact

-

High rigidity and durability, resistant to fading and wear

-

Suitable for both interior and exterior architectural applications

-

Enhances depth, dimension, and hierarchy of space design

-

Safe, eco-friendly, and easy to maintain

Applications of Water Ripple Stainless Steel

Thanks to its unique decorative effect and robust performance, water ripple stainless steel is widely adopted in both commercial and residential projects. Common applications include:

-

Wall panels and architectural cladding

-

Decorative ceiling designs

-

Elevator interiors and lobbies

-

Kitchen and bathroom backsplashes

-

Custom furniture and luxury fixtures

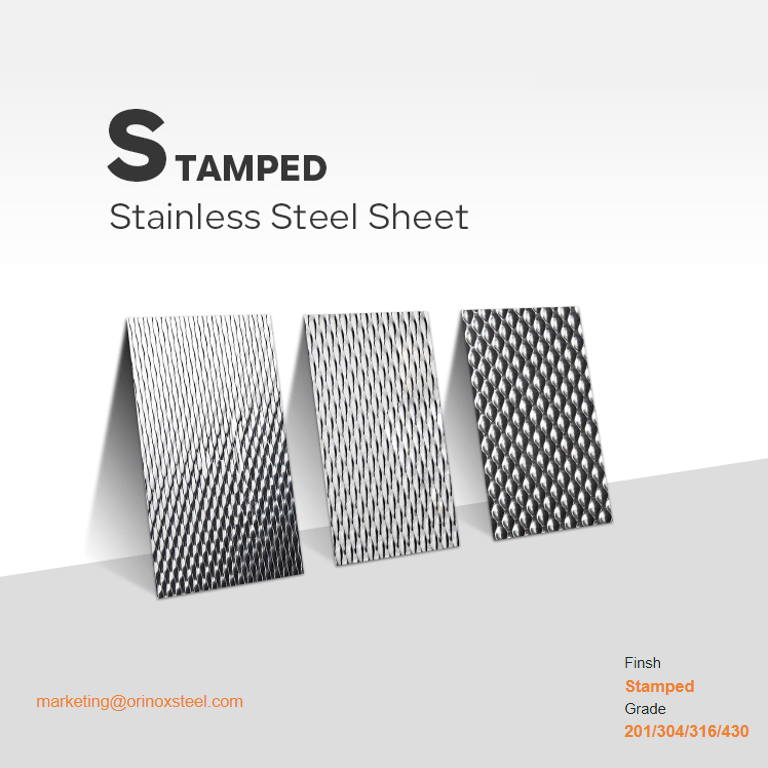

Top 7 Finish : Stamped

Stamped stainless steel is produced through a precise rolling or stamping process, where a die is used to press patterns, textures, or designs onto the surface of the sheet. This creates raised or recessed details that not only enhance the material’s decorative appeal but also improve its durability and functional performance. Stamped stainless steel combines strength with aesthetic versatility, making it suitable for a wide range of applications.

Key Features of Stamped Stainless Steel

-

Raised or recessed surface designs with high precision

-

Strong rigidity and long-lasting durability

-

Decorative appeal for modern architectural and industrial use

-

Excellent corrosion and rust resistance

-

Low-maintenance, easy to clean, and hygienic

Applications of Stamped Stainless Steel

Thanks to its durability and design flexibility, stamped stainless steel is widely used across multiple industries and design projects. Common applications include:

-

Decorative ceiling panels and interior design elements

-

Architectural wall cladding and façades

-

Furniture accents and custom decoration

-

Medical and laboratory equipment

-

Food industry applications requiring hygiene and durability

Top 8 Finish : Bead Blasted

Bead blasted stainless steel is produced by bombarding the sheet surface with fine glass beads or other abrasive materials under high pressure. This process creates a uniform, matte appearance that enhances both the visual appeal and functional performance of stainless steel sheets. The bead blasted finish is especially valued for its refined texture, anti-glare properties, and ability to hide fingerprints or minor surface defects.

Key Features of Bead Blasted Stainless Steel

-

High-grade, uniform matte finish with a sandblasted effect

-

Excellent resistance to acids and corrosion

-

Durable and long-lasting decorative performance

-

Eco-friendly, safe, and hygienic surface treatment

-

Easy to clean and maintain for practical use

Applications of Bead Blasted Stainless Steel

Thanks to its stylish appearance and reliable performance, bead blasted stainless steel is widely used in both decorative and industrial applications, including:

-

Modern building façades and exterior cladding

-

Elevator interiors and decorative panels

-

Furniture and interior design elements

-

Kitchen and custom appliance design

-

Signage, branding, and display panels

-

Medical and laboratory equipment surfaces

-

High-end household products and accessories

Top 9 Finish : Antique

Antique stainless steel sheets are specially processed to create a vintage, weathered, or retro-style surface effect. Through chemical corrosion and customized finishing techniques, each sheet develops a unique and artistic pattern, making it a popular choice for projects that emphasize classical aesthetics with modern durability.

Key Features of Antique Stainless Steel

-

Distinctive retro and vintage appearance

-

Wide variety of styles and patterns

-

Rich and vibrant colors

-

Strong artistic appeal for creative designs

-

Excellent acid and corrosion resistance

-

Long-lasting performance with minimal fading

Applications of Antique Stainless Steel

With their unique textures and artistic visual impact, antique stainless steel sheets are widely used in architectural and decorative projects that require a luxurious yet vintage style. Common applications include:

-

Ceiling and wall decoration

-

Furniture design and luxury fixtures

-

Building facades and cladding

-

Interior architectural accents

-

Artistic sculptures and installations

-

Branding signage and creative displays

-

Fashion accessories and jewelry design

Top 10 Finish : Laminated

Laminated stainless steel is created by bonding stainless steel sheets or coils with protective PET films, combining durability with versatile aesthetics. This process enhances cleanability, weather resistance, corrosion resistance, and chemical resistance, making it a highly practical and visually appealing material for modern architectural and interior applications.

Key Features of Laminated Stainless Steel

-

Unique and customizable pattern styles

-

Waterproof and fire-resistant

-

Excellent acid and corrosion resistance

-

Superior weather resistance for outdoor and indoor use

-

Anti-staining and easy maintenance

Applications of Laminated Stainless Steel

With a wide range of colors, patterns, and textured finishes, laminated stainless steel sheets are ideal for commercial, architectural, and decorative projects. Popular designs include wood grain and marble series, offering both style and functionality. Common applications include:

-

Architecture and interior design

-

Kitchen design and wall cladding

-

Furniture and cabinetry

-

Elevator interiors and decorative panels

-

Retail and commercial spaces

-

Transportation and vehicle interiors

Conclusion

The 10 stainless steel finishes introduced above represent the most popular and versatile decorative options in the market, each offering unique features and practical applications. From interior design to industrial projects, these finishes have become an integral part of modern architecture, furniture, appliances, and more.

Why Choose Orinox Steel?

At OrinoxSteel, we deliver high-quality decorative stainless steel sheets and panels trusted by architects, designers, and industries worldwide. Our decorative solutions combine aesthetics, durability, and functionality to meet diverse project requirements:

-

Wide Variety of Finishes: Including water ripple, embossed, etched, stamped, mirror, brushed, bead blasted, PVD color coating, antique, and laminated finishes — all designed to elevate interior and exterior spaces.

-

Premium Quality: Made from top-grade stainless steel (304, 316, 201, 430, etc.) with excellent corrosion resistance, scratch resistance, and long-lasting performance.

-

Customizable Solutions: Sheets and panels available in various sizes, thicknesses, textures, and colors to match your project vision.

-

Eco-Friendly & Safe: All products are non-toxic, easy to clean, and environmentally responsible.

-

Global Delivery & Support: Reliable logistics, competitive pricing, and expert technical guidance for design and installation.

With OrinoxSteel, you gain more than a supplier — you gain a trusted partner for decorative stainless steel solutions, ensuring your projects stand out with style and quality.

📩 Request a quote today and discover stainless steel decorative panels engineered for both beauty and performance.