Thin Wall Stainless Steel Tubing: Specs, Applications, Standards & Buying Guide

Thin Wall Stainless Steel Tubing: Complete Guide for Industrial Buyers

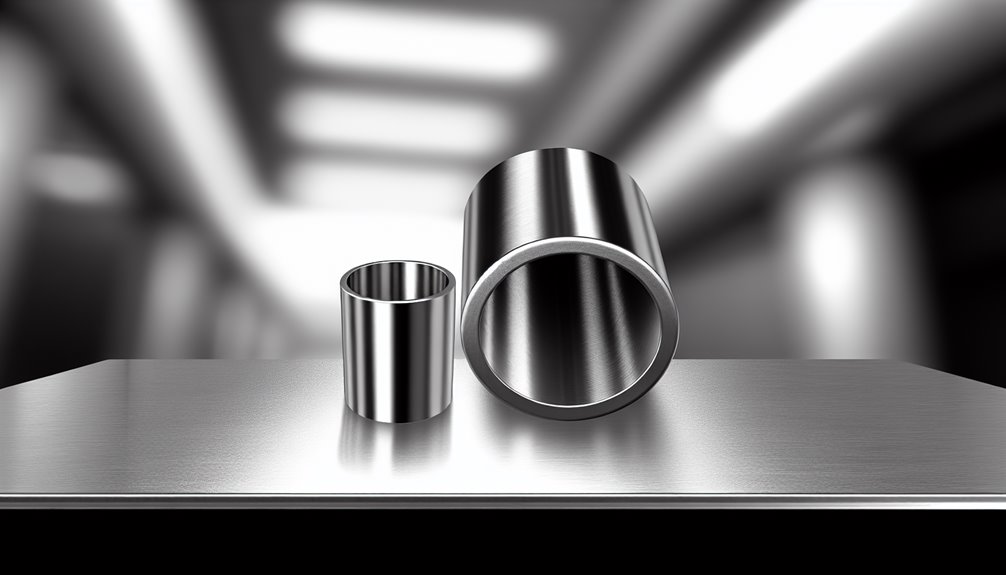

Thin wall stainless steel tubing refers to stainless steel tubes with reduced wall thickness compared to standard pipes, while still maintaining strength, durability, and corrosion resistance. Thanks to modern manufacturing technology, thin wall tubing delivers an excellent strength-to-weight ratio, making it ideal for aerospace, automotive, medical, food processing, and precision engineering industries.

Typical wall thickness ranges from 0.5mm to 1.5mm, depending on diameter and application.

Related Products:

Stainless Steel Tubes&Pipes Welded Stainless Steel Pipe Seamless Stainless Steel Pipe Decorative Stainless Steel Pipe

Key Takeaways

-

Lightweight yet strong, ideal for aerospace, automotive, and medical industries

-

Wall thickness typically ranges from 0.5mm to 1.5mm

-

Manufactured through extrusion, cold drawing, welding, and annealing

-

Complies with ASTM, EN, and ISO standards

-

High corrosion resistance and long service life

-

Cost depends on grade, size, finish, and order volume

What Is Thin Wall Stainless Steel Tubing?

Thin wall stainless steel tubing is designed with thinner walls than standard pipes, without sacrificing mechanical performance. Advanced forming and welding techniques ensure dimensional accuracy, surface quality, and structural integrity.

Typical Wall Thickness Range

-

Ultra-thin: 0.5 – 0.8 mm

-

Thin: 0.9 – 1.2 mm

-

Light: 1.3 – 1.5 mm

Actual thickness depends on diameter, pressure requirements, and application standards.

Manufacturing Process

The production of thin wall stainless steel tubing involves several precision-controlled steps:

-

Extrusion or Forming – Stainless steel strip or billet is shaped into tube form

-

Welding – High-frequency or laser welding ensures seam integrity

-

Cold Drawing – Improves accuracy, strength, and surface finish

-

Annealing – Relieves internal stress and improves ductility

-

Straightening & Cutting – Final sizing and length control

-

Inspection & Testing – Dimensional, chemical, and mechanical testing

This process ensures compliance with global standards and consistent quality.

Applications Across Industries

Aerospace

Used in hydraulic lines, structural components, and cooling systems due to high strength-to-weight ratio and heat resistance.

Automotive

Applied in fuel lines, exhaust systems, and structural parts to reduce vehicle weight and improve efficiency.

Medical Devices

Ideal for surgical instruments, implants, and medical tubing thanks to corrosion resistance and biocompatibility.

Food & Beverage

Used in sanitary pipelines, liquid transfer systems, and processing equipment due to easy cleaning and hygiene compliance.

Industrial & Chemical

Suitable for fluid transfer, heat exchangers, and process lines in corrosive environments.

Advantages of Thin Wall Stainless Steel Tubing

-

Lightweight Design – Reduces system weight and installation cost

-

High Strength – Maintains structural integrity under pressure

-

Corrosion Resistance – Performs well in humid, chemical, and marine environments

-

Long Service Life – Lower maintenance and replacement cost

-

Recyclable Material – 100% recyclable, eco-friendly choice

International Standards and Certifications

Thin wall stainless steel tubing commonly follows:

| Standard Type | Standard |

|---|---|

| ASTM | A554, A270, A249, A269 |

| EN | EN 10217-7, EN 10296-2, EN 10088 |

| ISO | ISO 9001, ISO 14001 |

| Sanitary | 3-A, ASME BPE |

| Marine | DNV, ABS, Lloyd’s |

| EU | CE Marking |

These ensure dimensional accuracy, material performance, and global compliance.

How to Choose the Right Thin Wall Stainless Steel Tubing

1. Material Grade

-

304 – General purpose, food, decoration

-

316 / 316L – Chemical, marine, pharmaceutical

-

201 – Cost-sensitive applications

-

430 – Decorative and indoor use

2. Surface Finish

-

Polished (Mirror, BA, 2B) – Food, medical, decorative

-

Matte or Brushed – Industrial and architectural use

3. Dimensions

-

Choose diameter and thickness based on pressure, flow, and load

-

Tight tolerances are critical for precision systems

4. Environment

-

Consider corrosion, humidity, chemicals, and temperature

-

Prefer high recycled content for sustainability goals

Pricing Factors

Pricing of thin wall stainless steel tubing is affected by:

-

Material grade (201 vs 304 vs 316)

-

Size and wall thickness

-

Surface finish

-

Order quantity

-

Manufacturing complexity

-

Market demand and raw material cost

Cost Optimization Strategies

-

Bulk purchasing for lower unit price

-

Optimize design to reduce unnecessary thickness

-

Compare grades for performance vs budget

-

Choose stable suppliers with efficient logistics

Sourcing Best Practices

Evaluate Manufacturers

-

Check factory capability and equipment

-

Verify certifications (ISO, ASTM, EN)

-

Review export experience and customer feedback

Required Documents

-

Mill Test Certificate (MTC)

-

Chemical and mechanical test reports

-

Traceability records

-

Compliance certificates

Supply Chain Strategy

-

Diversify suppliers

-

Consider lead time and shipping routes

-

Manage geopolitical and logistics risks

Maintenance and Longevity

-

Regular inspections for corrosion or wear

-

Proper cleaning to avoid residue buildup

-

Control operating environment

-

Apply protective coatings if needed

FAQ

How is thin wall stainless steel tubing made?

By forming, welding, cold drawing, and annealing, followed by strict testing.

Is it recyclable?

Yes, stainless steel is 100% recyclable.

What is the typical lead time?

Usually 4–12 weeks for custom sizes, depending on complexity and volume.

How does it perform in thermal applications?

Stainless steel has moderate thermal conductivity, suitable for many industrial uses but not high-insulation systems.

Conclusion

Thin wall stainless steel tubing combines strength, precision, and corrosion resistance in a lightweight form. It is widely used in aerospace, automotive, medical, food, chemical, and industrial sectors. By choosing the right grade, size, finish, and certified supplier, buyers can achieve long-term reliability and cost efficiency.

If you are sourcing thin wall stainless steel tubing for global projects, focus on standards compliance, manufacturing capability, and supply chain stability to ensure consistent quality and performance.