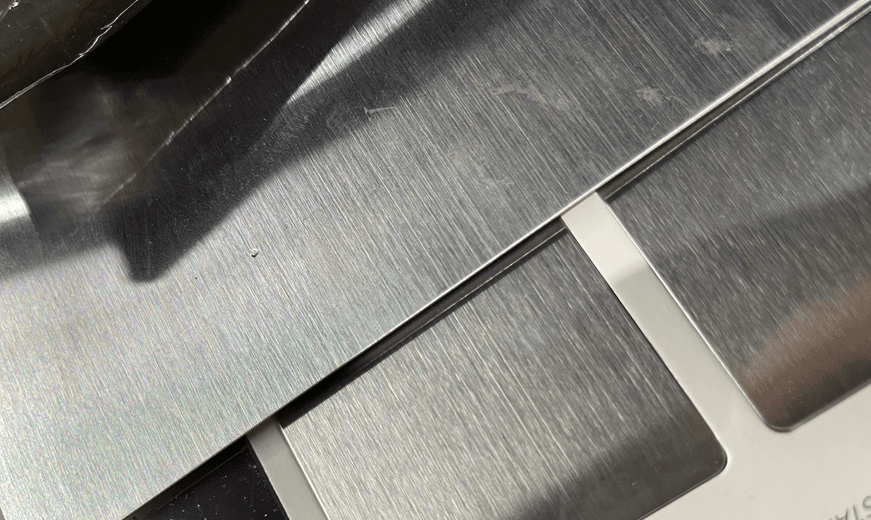

Stainless steel sheets for countertops

Stainless Steel Sheets for Countertops: A Comprehensive Guide

Related Products:

304 Stainless Steel Sheet 316 Stainless Steel Sheet water ripple Stainless Steel Sheet embossed Stainless Steel Sheet hairline Stainless Steel Sheet

Choosing the Right Steel Grade

Two primary stainless steel grades are commonly used for countertops, each offering distinct advantages:

-

Grade 304

The most popular choice for residential countertops, Grade 304 stainless steel contains 18% chromium and 8% nickel. Known for its excellent corrosion resistance, it’s perfect for kitchen or bathroom settings where exposure to water, food acids, and cleaning agents is frequent. The corrosion resistance comes from a passive oxide layer that forms naturally on the surface, offering long-lasting protection.

-

Grade 316

For areas subjected to harsher conditions, Grade 316 stainless steel is a superior option. It includes molybdenum in the alloy, making it highly resistant to corrosion in environments with high humidity or saltwater exposure. Grade 316 is ideal for coastal homes or commercial kitchens where resilience to corrosion is crucial.

Surface Treatments and Their Benefits

Stainless steel sheets can be treated with various surface finishes to enhance their look and functionality:

-

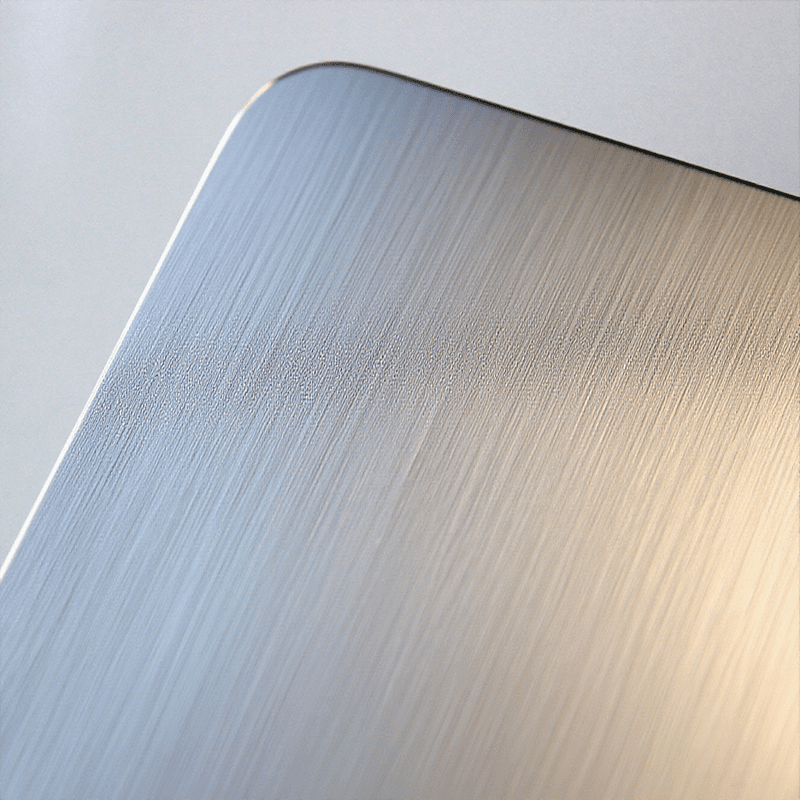

Brushed (Satin) Finish

One of the most common finishes, this involves creating fine, parallel lines on the surface through mechanical abrasion. The result is a refined, non-reflective appearance that is also effective at hiding fingerprints and minor scratches.

-

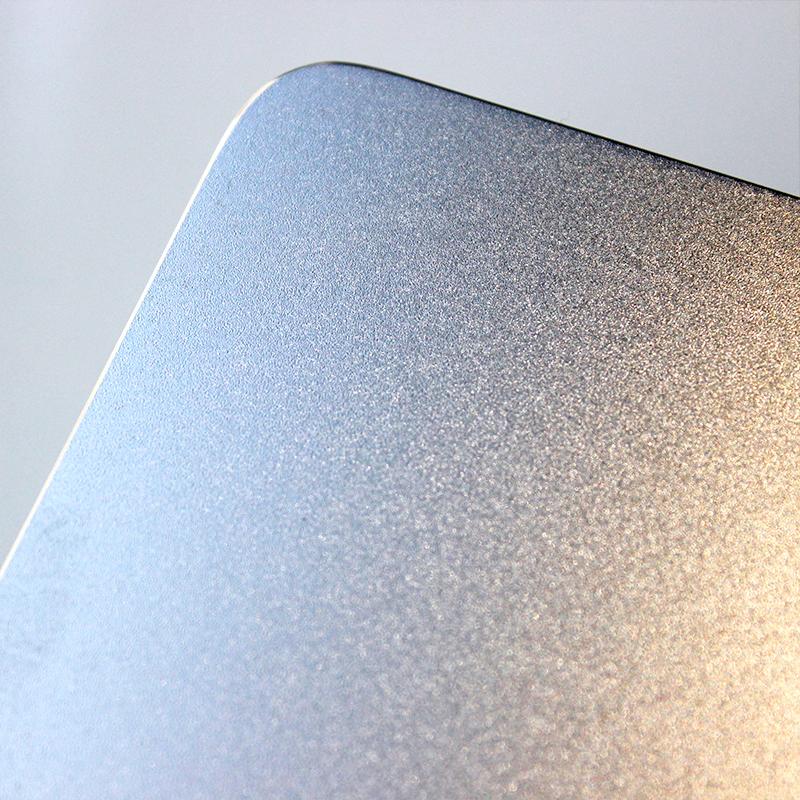

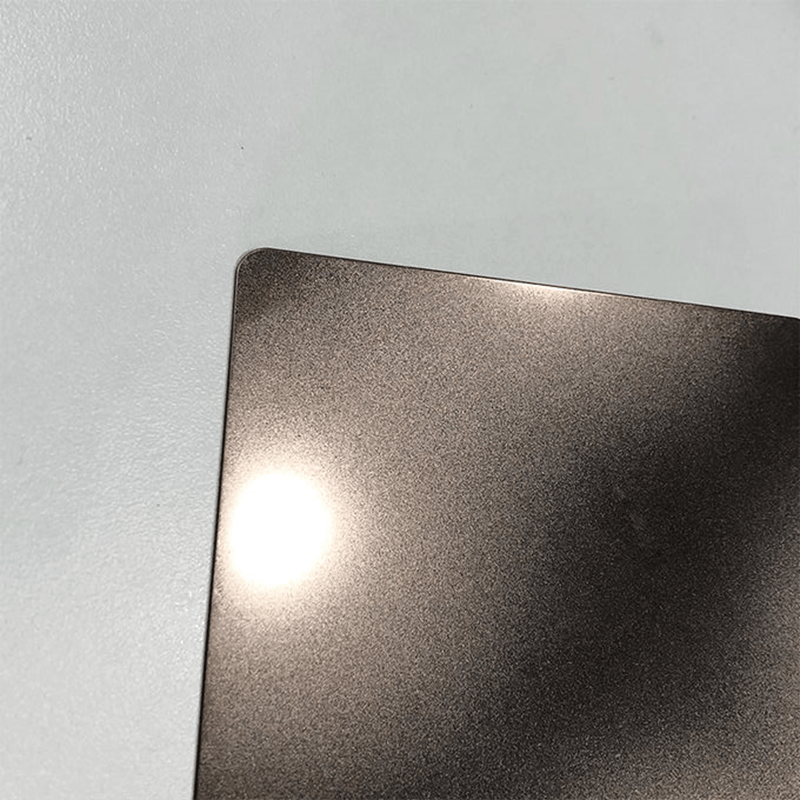

Sandblasted Finish

In this treatment, high-pressure abrasive particles are applied to the steel surface, giving it a matte, textured look. This finish enhances fingerprint resistance and provides better grip, making it ideal for areas like kitchen sinks. It also improves scratch resistance due to its rougher surface.

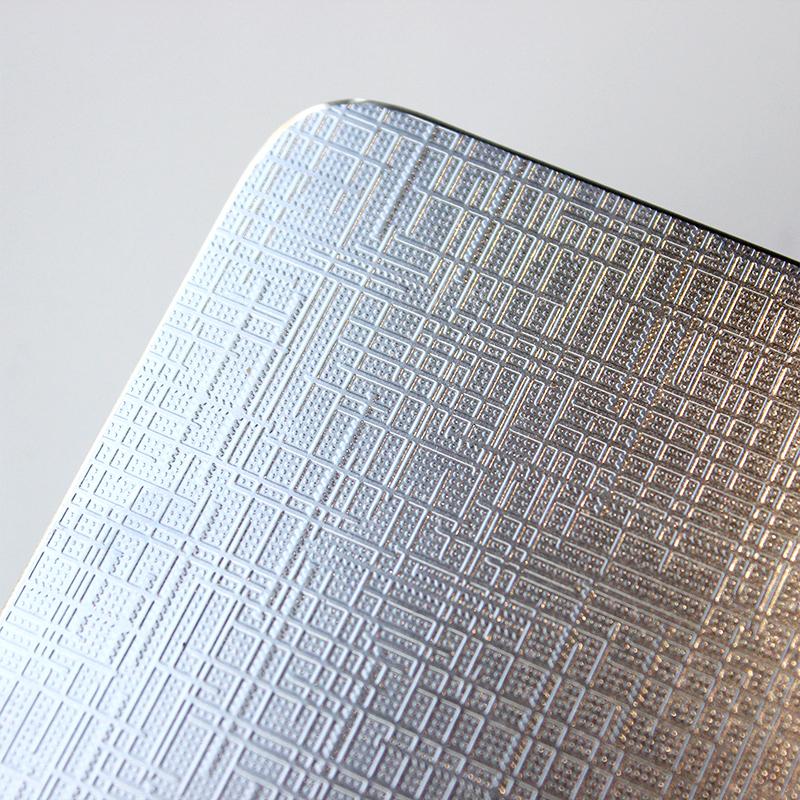

Embossed (Patterned) Finish

Available in various patterns such as hammered, wavy, or diamond-plate, this finish increases the surface area, promoting heat dissipation. The raised patterns distribute impacts more evenly, reducing the risk of dents if a heavy object is dropped.

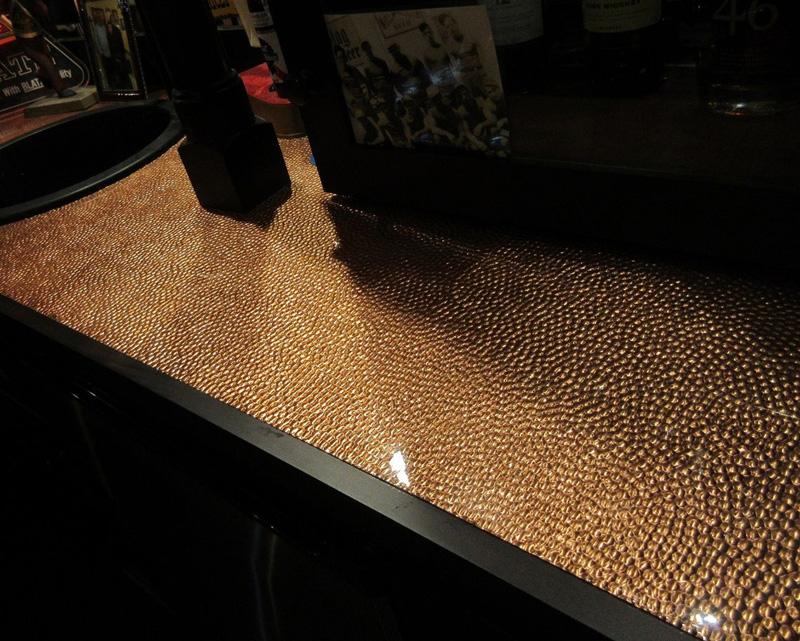

Hammered Finish

A unique variation of embossed finishes, the hammered effect provides a rustic or industrial charm. Its uneven surface resists fingerprints and minor scratches, although the indentations can trap dirt. Cleaning is simple with a soft brush and mild detergent.

-

Fingerprint-Resistant Finish

For low-maintenance options, fingerprint-resistant finishes apply a thin, transparent coating to the stainless steel surface. This finish helps to repel smudges and maintain the steel’s shine for longer, reducing the frequency of cleaning.

Optimal Thickness for Stainless Steel Sheets

The thickness of stainless steel sheets for countertops depends on the intended application:

-

Residential Kitchens

For typical home kitchens, a thickness of 0.8 – 1.0mm is sufficient. This offers a good balance of durability and cost, capable of handling daily kitchen tasks like food preparation and the occasional impact.

-

Commercial Kitchens

In environments with heavy use, such as professional kitchens, thicker sheets of 1.2 – 3.0mm are recommended. These sheets can better withstand the wear and tear of constant use, heavy kitchen equipment, and rough handling.

Key Performance Features of Stainless Steel Sheets for Countertops

-

Heat Resistance

Stainless steel sheets excel in handling high temperatures. Whether placing a hot pan directly onto the countertop or dealing with heated cookware, the material will not warp, melt, or discolor.

-

Corrosion Resistance

Thanks to the chromium content, stainless steel naturally forms a protective oxide layer that prevents rusting or corrosion when exposed to water, food acids, or cleaning products.

-

Acid Resistance

The alloy composition of stainless steel sheets gives them a strong resistance to acidic substances, such as tomato sauce, citrus juices, and vinegar. This feature makes them an ideal choice for food preparation areas.

-

Antibacterial Properties

Stainless steel is naturally resistant to bacteria, offering a hygienic solution for kitchens and bathrooms. Its smooth surface doesn’t allow bacteria to thrive, making it an excellent choice for maintaining a clean environment.

-

Scratch Resistance

While no material is entirely scratch-proof, stainless steel is relatively resistant to scratches. A brushed or embossed finish can help conceal scratches, and in some cases, minor scuffs can be buffed out using appropriate stainless-steel polishing compounds.

-

Seamless Welding

Stainless steel countertops can be fabricated with seamless welding techniques, ensuring a smooth and continuous surface without visible joints. This not only improves the aesthetic appearance but also makes the countertop easier to clean.

Conclusion

When selecting stainless steel sheets for countertops, the material offers a wide range of benefits, including durability, corrosion resistance, and versatility. With various finishes and thickness options available, you can choose a countertop that meets both your functional and aesthetic needs. Whether for residential or commercial use, stainless steel sheets are a timeless choice that combines style with long-lasting performance.

Where can I buy high-quality, affordable stainless steel sheets?

Once a series of technical parameters are determined, the next step is to find high-quality suppliers.