Stainless Steel Sheet Export Packing Process

Safe Packaging and Loading for Global Shipment – Stainless Steel Sheet

Do you know how stainless steel sheets are packed and loaded for international shipment?

Proper export packing is critical to prevent surface damage, rust, deformation, and contamination during long-distance transportation.

With more than 15 years of experience in exporting stainless steel sheets, OrinoxSteel follows a strict and professional export packing and loading process. Below is the complete stainless steel sheet export packing process, from material selection to final shipment.

Related Products:

Related Products:

Hairline Stainless Steel Sheet Water Ripple Stainless Steel Sheet Embossed Stainless Steel Sheet 201 Stainless Steel Sheet 304 Stainless Steel Sheet 316 Stainless Steel Sheet 430 Stainless Steel Sheet

Step 1: Export Packaging Material Selection

Choose packaging materials that meet international export standards, including:

-

Fumigated wooden cases

-

Wooden pallets

-

Steel strips and binding belts

-

Protective films and corner guards

All materials must have enough strength and stability to protect stainless steel sheets from impact, moisture, and contamination.

Step 2: Packaging Preparation

According to the size, thickness, and quantity of the stainless steel sheets:

-

Prepare suitable pallets or wooden cases

-

Check packaging materials are clean and dry

-

Ensure no dust, moisture, or harmful substances

Proper preparation ensures the packing environment meets export safety standards.

Step 3: Surface Cleaning and Pre-Treatment

Before packing, stainless steel sheets are:

-

Cleaned to remove oil, dust, and impurities

-

Dried completely

-

Inspected for surface quality

This step ensures no contamination or corrosion risk during transportation.

Step 4: Packing and Fixing

Place stainless steel sheets into the packaging:

-

Use wooden strips or corner protectors

-

Add foam, paper, or plastic film between sheets

-

Fix packages with steel straps

This prevents movement, scratching, or collision during shipping.

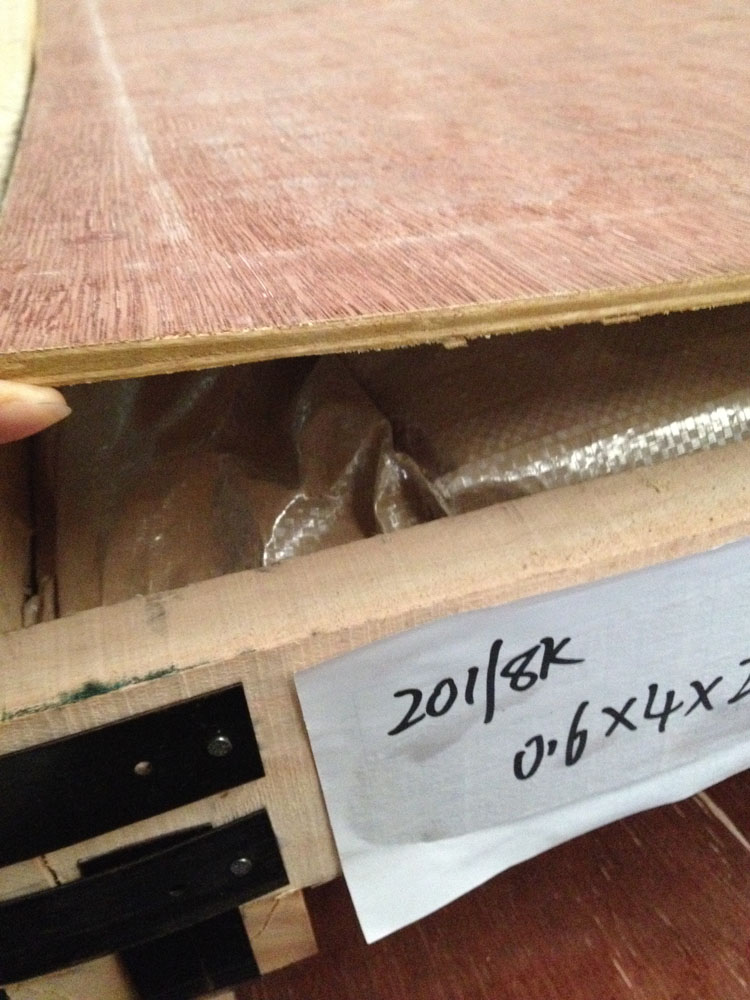

Step 5: Identification and Export Labeling

Each package is clearly labeled with:

-

Product grade and size

-

Quantity and net/gross weight

-

Heat number or batch number

-

Export marks and handling symbols

Labels follow international shipping and customs requirements.

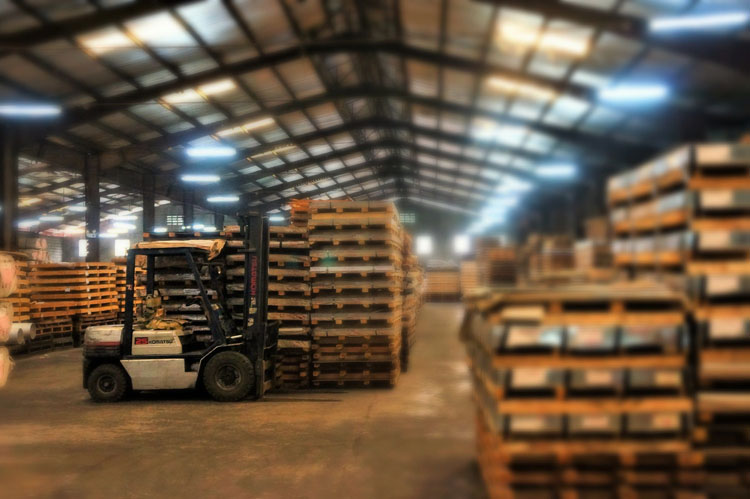

Step 6: Loading and Containerization

During container loading:

-

Arrange packages evenly

-

Use wooden blocks and wedges for fixing

-

Avoid stacking overload

-

Ensure center of gravity is stable

Proper container loading is critical for long-distance sea transportation.

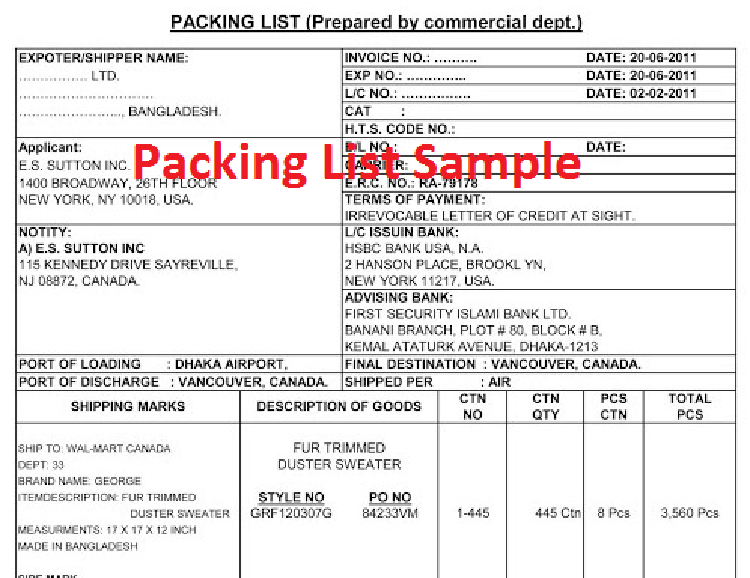

Step 7: Packing List and Export Documents

Prepare complete export documents, including:

-

Commercial invoice

-

Packing list

-

Bill of lading

-

Shipping contract

Accurate documents ensure smooth customs clearance.

Step 8: Shipping and Transportation

Transport the containers to the port and arrange shipment:

-

Follow international shipping rules

-

Monitor cargo condition

-

Ensure safe arrival at destination

Professional logistics management ensures stainless steel sheets reach global customers safely.

Conclusion

A professional stainless steel sheet export packing process includes:

-

Packaging material selection

-

Preparation

-

Surface cleaning

-

Packing and fixing

-

Labeling

-

Container loading

-

Document preparation

-

Shipping

By following strict export standards and professional loading methods, stainless steel sheets can be safely delivered to customers around the world with minimal risk of damage.