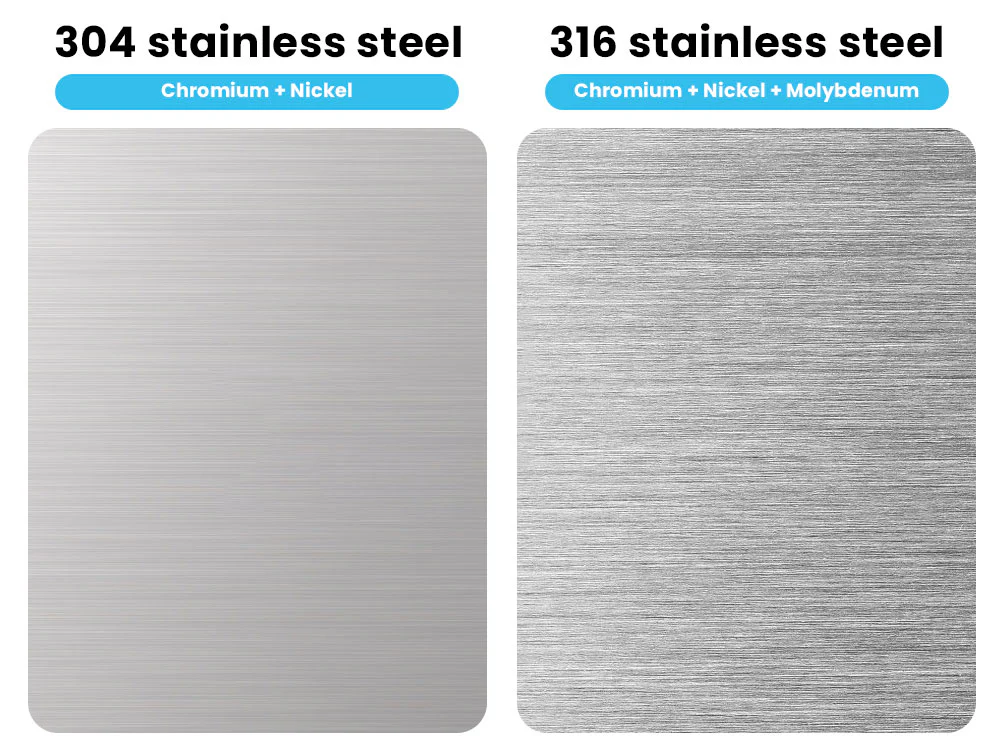

Top 2 most commonly used stainless steel sheets in storage tanks

304 vs 316 Stainless Steel Sheet for Storage Tanks – How to Choose the Best Material for Tank Manufacturing

Choosing the right stainless steel sheet for storage tanks depends on several key factors, including the type of substance stored, environmental conditions, temperature, and regulatory requirements. Among all stainless steel grades, 300 series stainless steel, especially 304 and 316 stainless steel sheets, are the most commonly used materials in tank manufacturing.

Both grades offer excellent corrosion resistance and durability, but they are designed for different working environments. This guide will help you understand the differences between 304 vs 316 stainless steel sheet for tanks and how to choose the right one for your application.

Связанные продукты:

Лист из нержавеющей стали 304 Лист из нержавеющей стали 316 Рулон из нержавеющей стали 304 Рулон из нержавеющей стали 316

304 Stainless Steel Sheet Used in Storage Tanks

304 stainless steel is the most widely used grade in tank manufacturing due to its balanced performance and cost.

Advantages of 304 Stainless Steel for Tanks

1. Good Corrosion Resistance

304 stainless steel resists most oxidizing acids and common corrosive environments. It is suitable for storing:

-

Water

-

Food and beverage products

-

Mild chemicals

2. Excellent Fabrication Performance

304 stainless steel sheet is easy to:

-

Cut

-

Weld

-

Bend

-

Form into different tank shapes and sizes

This makes it ideal for customized tank fabrication.

3. Hygienic and Easy to Clean

Its smooth, non-porous surface makes 304 stainless steel suitable for:

-

Food processing tanks

-

Beverage tanks

-

Pharmaceutical and cosmetic tanks

4. Cost-Effective Choice

Compared with higher alloy grades, 304 stainless steel offers a good balance between price and performance.

5. Wide Temperature Range

304 stainless steel performs well in both high and low temperature environments, making it suitable for most industrial tanks.

Typical Applications of 304 Stainless Steel Tanks

-

Water storage tanks

-

Food and beverage tanks

-

Milk and juice tanks

-

Mild chemical storage tanks

-

General industrial tanks

316 Stainless Steel Sheet Used in Storage Tanks

316 stainless steel is designed for more aggressive and corrosive environments.

Advantages of 316 Stainless Steel for Tanks

1. Superior Corrosion Resistance

316 stainless steel contains molybdenum, which greatly improves resistance to:

-

Chlorides

-

Seawater

-

Harsh industrial environments

2. Better Chemical Resistance

316 stainless steel performs well when storing:

-

Strong acids

-

Alkalis

-

Chemical solutions

3. High Temperature Performance

It maintains strength and corrosion resistance under elevated temperatures.

4. Medical and Pharmaceutical Grade

Because of its high purity and corrosion resistance, 316 stainless steel is widely used in:

-

Pharmaceutical tanks

-

Medical equipment tanks

-

High-cleanliness applications

5. Long Service Life

Excellent resistance to pitting and crevice corrosion ensures long-term durability in harsh conditions.

Typical Applications of 316 Stainless Steel Tanks

-

Chemical storage tanks

-

Pharmaceutical tanks

-

Marine and coastal tanks

-

High-salt or chloride environments

-

High-temperature process tanks

304 vs 316 Stainless Steel Sheet for Tanks

| Пункт | нержавеющей стали 304 | нержавеющая сталь 316 |

|---|---|---|

| Коррозионная стойкость | Good | Excellent |

| Chloride Resistance | Limited | Strong |

| Chemical Resistance | Medium | High |

| Стоимость | Lower | Higher |

| Fabrication | Easy | Easy |

| Typical Use | Water, food, mild chemicals | Chemicals, marine, pharma |

How to Choose Between 304 and 316 for Tanks

Choose 304 stainless steel sheet if:

-

You store water, food, beverages, or mild chemicals

-

The environment is not highly corrosive

-

You want a cost-effective solution

Choose 316 stainless steel sheet if:

-

The tank is used in coastal or marine areas

-

High chloride or salt exposure exists

-

Strong chemicals are stored

-

Long-term corrosion resistance is critical

Best Stainless Steel Series for Storage Tanks

The most commonly used stainless steel sheets for tanks come from the 300 series stainless steel, especially:

-

304 stainless steel sheet

-

316 stainless steel sheet

These grades offer the best combination of corrosion resistance, fabrication performance, and durability for most tank manufacturing projects.

Заключение

The best stainless steel sheet for storage tanks usually comes from the 300 series stainless steel, with 304 and 316 stainless steel being the two most popular choices.

-

304 stainless steel is suitable for most general-purpose tanks, especially for water, food, and mild chemical storage.

-

316 stainless steel is ideal for aggressive environments, chemical storage, marine conditions, and pharmaceutical applications.

When selecting stainless steel for tank manufacturing, always consider:

-

The substance stored

-

Operating environment

-

Temperature

-

Corrosion requirements

-

Budget

Choosing the right grade ensures longer service life, better safety, and lower maintenance costs for your storage tanks.