Stainless Steel Perforated Sheet: Properties, Patterns, Manufacturing Process & Applications

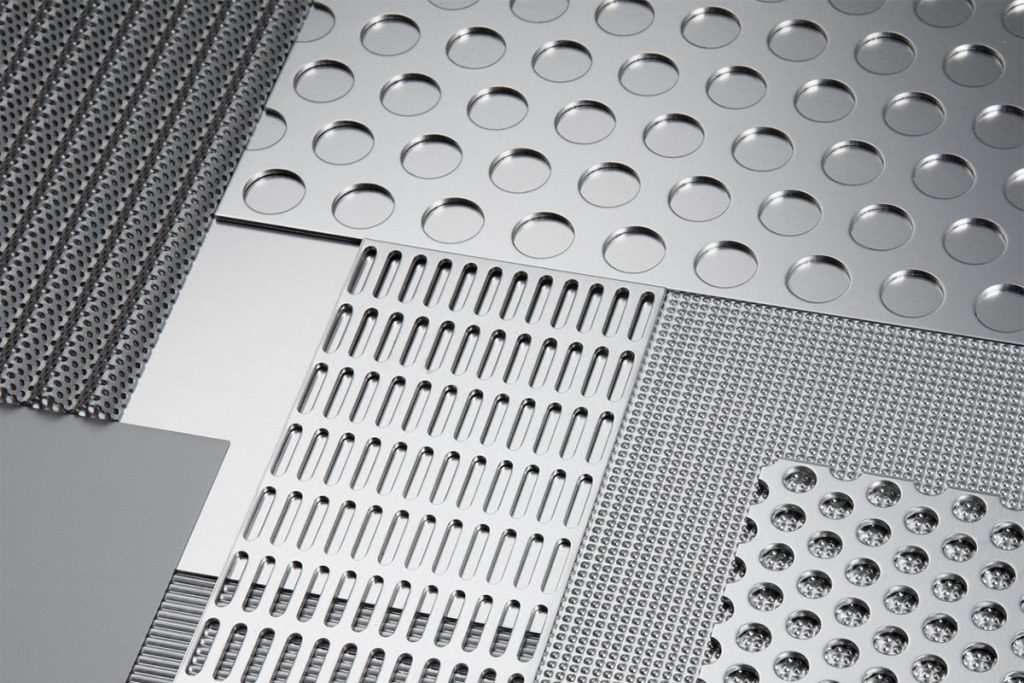

Stainless Steel Perforated Sheets – A New Material For Modern Industrial Aesthetics

In modern architecture, industrial manufacturing, and interior design, stainless steel perforated sheet has become a highly versatile material that balances functionality with aesthetics. From building facades that filter sunlight, to acoustic panels that absorb noise, to industrial screens used in filtration systems, perforated stainless steel sheets quietly redefine how materials interact with space, light, and airflow.

Combining durability, corrosion resistance, and design flexibility, stainless steel perforated metal sheets are widely used across architectural, industrial, and commercial projects worldwide.

Связанные продукты:

Лист нержавеющей стали Hairline Лист из нержавеющей стали с водяным узором Рифлёный лист из нержавеющей стали Лист из нержавеющей стали 201 Лист из нержавеющей стали 304 Лист из нержавеющей стали 316 Лист из нержавеющей стали 430

What Is Stainless Steel Perforated Sheet?

A stainless steel perforated sheet is a flat metal sheet made from stainless steel, featuring regularly or irregularly arranged holes created through precision punching or laser cutting. Compared with solid stainless steel plates, perforated sheets transform the material from a simple barrier into a multifunctional medium that allows light transmission, ventilation, drainage, sound control, and filtration.

Common stainless steel grades used for perforated sheets include:

-

304 / 304L stainless steel – excellent corrosion resistance and formability

-

316 / 316L stainless steel – superior resistance to chemicals and marine environments

These grades make perforated stainless steel suitable for indoor decoration, outdoor architecture, high-humidity areas, and corrosive environments.

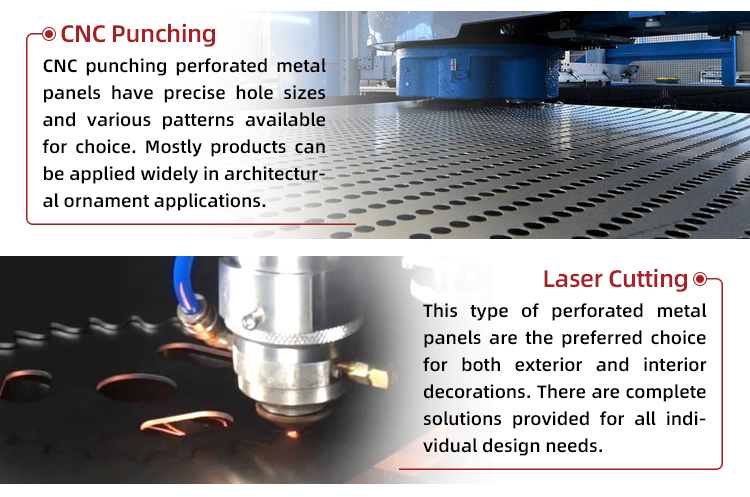

Manufacturing Process of Stainless Steel Perforated Sheet

The production of perforated stainless steel sheets requires precise control at every stage to ensure consistent hole size, spacing, and structural strength.

1. Material Selection

High-quality stainless steel sheets with thickness typically ranging from 0.5 mm to 6.0 mm are selected based on application requirements.

2. CNC Programming

Punching paths and hole patterns are programmed according to engineering drawings or custom designs.

3. Perforating

Perforation is carried out using CNC punching machines or laser cutting, ensuring accuracy and repeatability.

4. Surface Treatment

Optional surface finishes include:

-

Polishing

-

Brushed finish

-

Mirror finish

-

Sandblasting

-

PVD color coating

5. Forming

Sheets can be bent, rolled, or formed into three-dimensional shapes to meet project needs.

6. Cleaning & Packaging

Finished products are cleaned to remove residues and packed with protective materials for safe transportation.

Key Features of Stainless Steel Perforated Sheets

1. Excellent Physical Properties

-

High strength and corrosion resistance

-

Up to 30% lighter than solid stainless steel sheets

-

Good ventilation, drainage, and light transmission

2. Functional Performance

-

Effective filtration and screening

-

Sound absorption and noise reduction

-

Adjustable balance between visibility and privacy

3. Design Flexibility

-

Wide range of hole shapes and layouts

-

Rich surface textures through finishing processes

-

Dynamic light and shadow effects in architectural applications

4. Sustainability Advantages

-

100% recyclable material

-

Long service life reduces maintenance and replacement costs

-

Supports natural ventilation and daylighting, improving energy efficiency

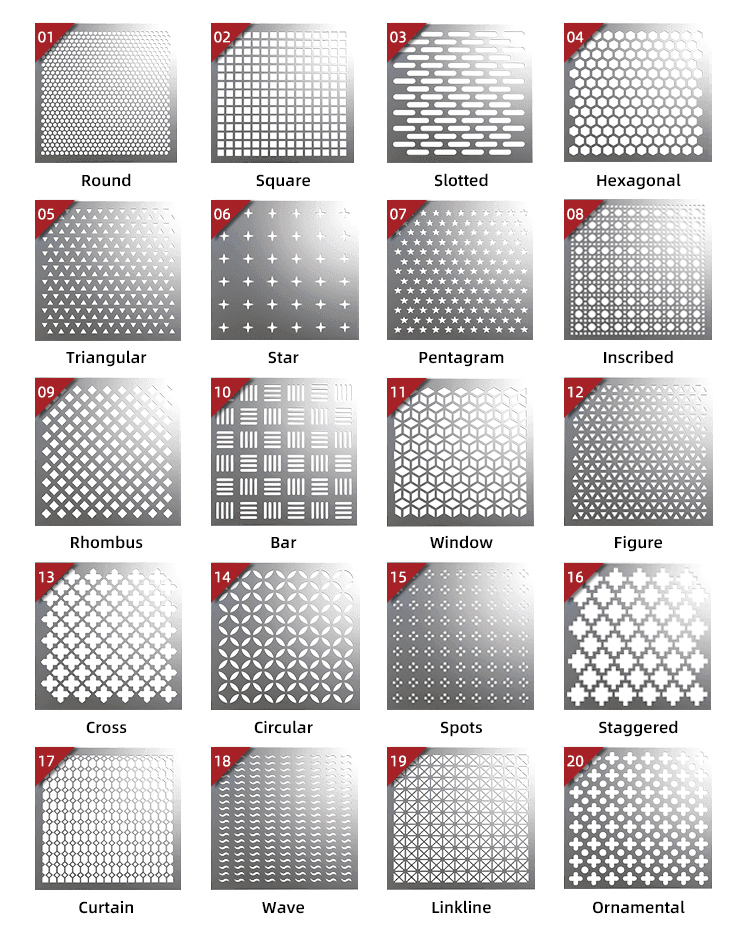

Perforation Pattern Options

Advances in manufacturing technology allow stainless steel perforated sheets to support both standard and highly customized designs.

Advances in manufacturing technology allow stainless steel perforated sheets to support both standard and highly customized designs.

1. Standard Patterns

-

Round hole perforation – most common, uniform appearance

-

Square hole perforation – modern and industrial style

-

Rectangular hole perforation – directional visual effect

2. Advanced Patterns

-

Gradient hole density designs

-

Mixed geometric perforations

-

Directional or linear arrangements

3. Custom Perforated Designs

-

Logo and text perforation

-

Image-based perforation using hole density

-

Parametric and algorithm-generated patterns

These options allow architects and designers to match both functional requirements and aesthetic goals.

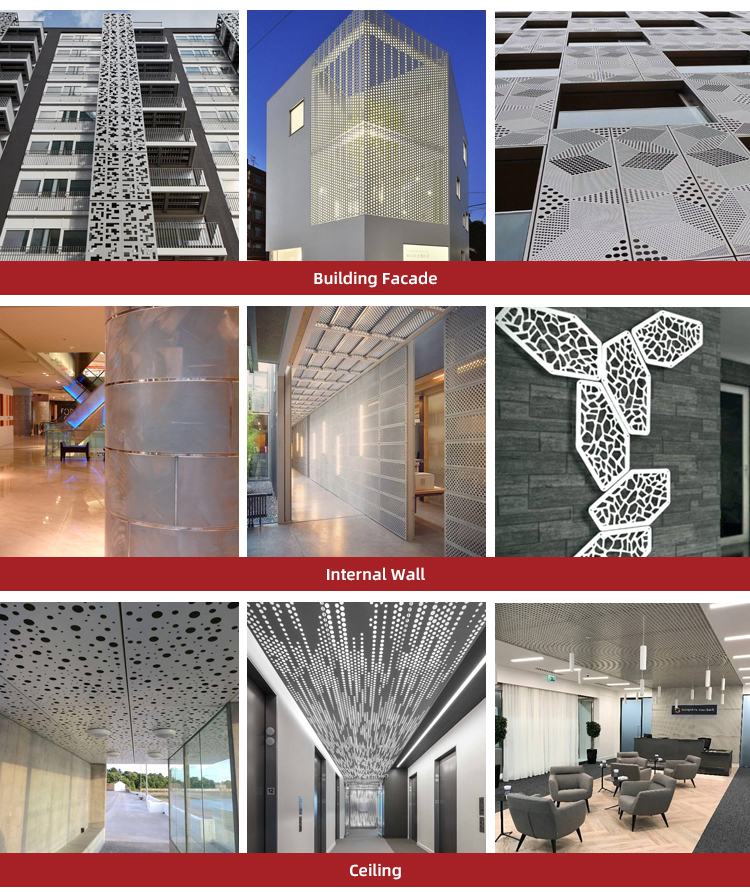

Applications of Stainless Steel Perforated Sheet

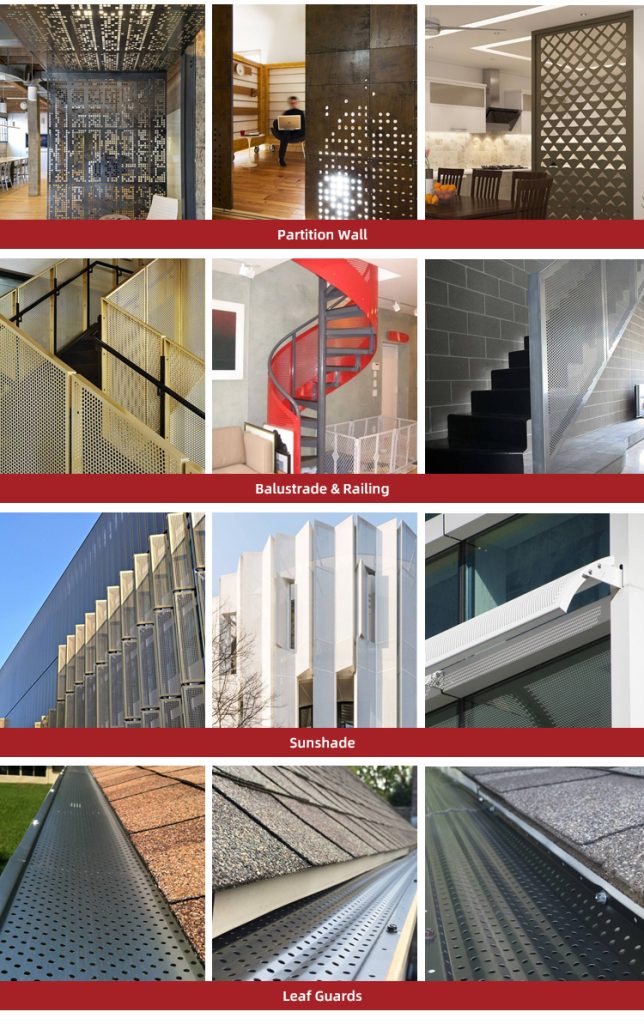

1. Architecture & Landscape

-

Building facades and curtain walls

-

Interior partitions and ceilings

-

Railings, fences, and safety barriers

-

Landscape installations and public art

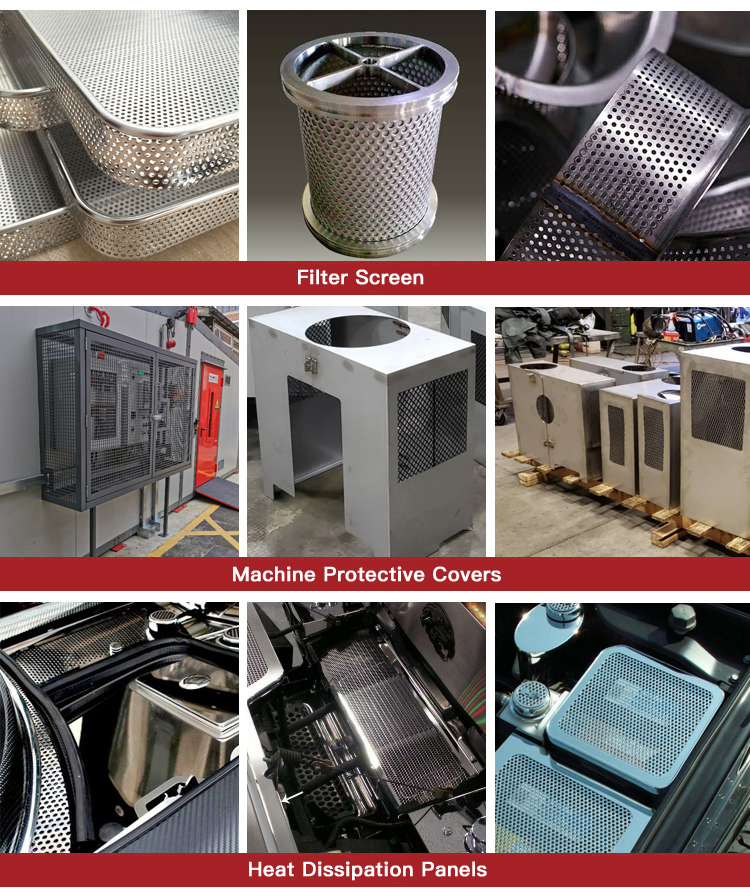

2. Industrial & Manufacturing

-

Screening and filtration systems

-

Machine guards and protective covers

-

Heat dissipation panels for equipment and electronics

3. Commercial & Residential Spaces

-

Retail and brand-focused interior decoration

-

Furniture panels and decorative screens

-

Acoustic walls for conference rooms, theaters, and music halls

In recent years, stainless steel perforated sheets have played a growing role in green building design, helping regulate indoor microclimates and reduce energy consumption.

Заключение

From an industrial material to a design-driven architectural element, stainless steel perforated sheet bridges engineering performance and visual expression. Through precisely engineered perforations, it redefines the relationship between material and space, function and form.

Whether used for architectural facades, industrial filtration, or decorative interiors, perforated stainless steel sheets provide a durable, sustainable, and highly customizable solution for modern projects.

As global demand for high-performance and visually distinctive materials continues to grow, stainless steel perforated metal sheets will remain a key material in modern industrial aesthetics.