Best Stainless Steel Checkered Plate Pattern for Flooring Applications

Best Stainless Steel Checkered Plate Pattern for Flooring Applications

Stainless steel checkered plate is widely used in flooring systems due to its excellent anti-slip performance, durability, and corrosion resistance. The raised surface patterns significantly improve traction, making it a preferred material for industrial floors, ramps, stair treads, and public walkways.

However, different checkered patterns offer different slip resistance levels, cleaning difficulty, and visual effects. Choosing the right stainless steel checkered plate pattern for flooring depends heavily on the application environment, safety requirements, and maintenance needs.

So, which stainless steel checkered plate pattern is best for flooring? Let’s break it down.

Связанные продукты:

Лист нержавеющей стали Hairline Лист из нержавеющей стали с водяным узором Рифлёный лист из нержавеющей стали Лист из нержавеющей стали 201 Лист из нержавеющей стали 304 Лист из нержавеющей стали 316 Лист из нержавеющей стали 430

Common Stainless Steel Checkered Plate Patterns & Their Features

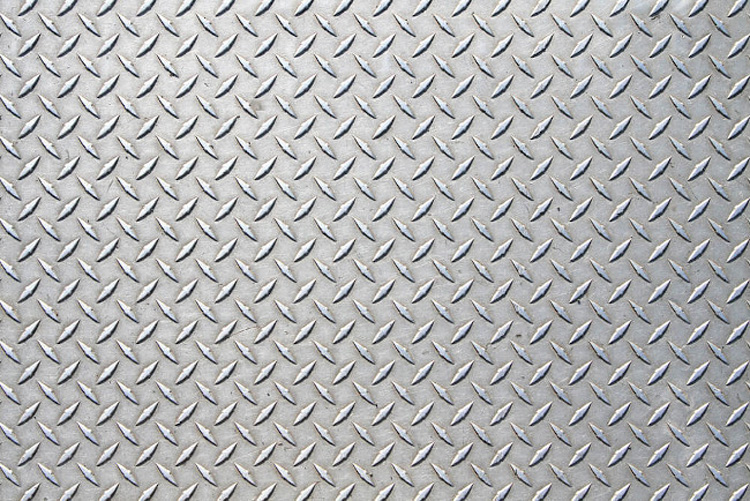

1. Diamond Pattern Stainless Steel Checkered Plate

The diamond pattern, also known as stainless steel diamond plate, is the most commonly used pattern for flooring worldwide.

The diamond pattern, also known as stainless steel diamond plate, is the most commonly used pattern for flooring worldwide.

Преимущества

-

Excellent anti-slip performance due to raised diamond-shaped protrusions

-

Height typically ranges from 2–6 mm, providing strong grip

-

Performs well in wet, oily, or greasy environments

Disadvantages

-

Deeper grooves may trap dirt or debris

-

Requires more frequent cleaning in hygiene-sensitive areas

-

Aggressive surface may accelerate footwear wear

Best Flooring Applications

-

Industrial floors and workshops

-

Factories and warehouses

-

Marine decks and offshore platforms

-

Stair treads and high-risk slip areas

Recommended Grades: 304 / 316 / 316L stainless steel

Typical Thickness: 3–6 mm

2. Lentil (Bean) Pattern Stainless Steel Checkered Plate

The lentil pattern features smooth, rounded raised dots, offering a balance between slip resistance and easy cleaning.

The lentil pattern features smooth, rounded raised dots, offering a balance between slip resistance and easy cleaning.

Преимущества

-

Moderate anti-slip performance

-

Easier to clean than diamond pattern

-

Hygienic surface suitable for regulated environments

Disadvantages

-

Lower grip compared to diamond pattern

-

Not suitable for heavy oil or extreme slip-risk areas

Best Flooring Applications

-

Commercial kitchens

-

Food processing plants

-

Hospitals and laboratories

-

Public indoor walkways

Recommended Grades: 304 / 316L

Compliance: Suitable for food and sanitation environments

3. Teardrop Pattern Stainless Steel Checkered Plate

The teardrop pattern combines directional grip with improved debris and water drainage.

The teardrop pattern combines directional grip with improved debris and water drainage.

Преимущества

-

Balanced traction and drainage performance

-

Reduced debris accumulation compared to diamond pattern

Disadvantages

-

Less common in the market

-

Slightly higher cost due to limited production

Best Flooring Applications

-

Outdoor platforms

-

Light industrial floors

-

Areas exposed to rain or moisture

Recommended Grades: 316 / 316L for corrosion resistance

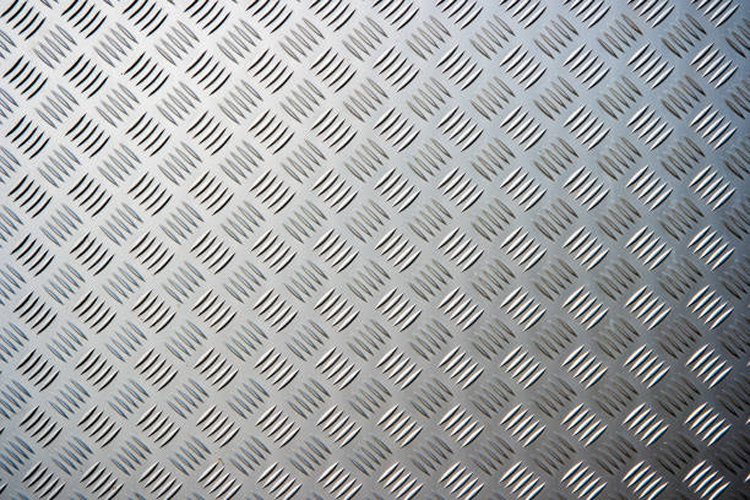

4. Linear Pattern Stainless Steel Checkered Plate (2 Bar / 3 Bar / 5 Bar)

Linear or bar-pattern checkered plates provide directional slip resistance, commonly used in ramps and walkways.

Linear or bar-pattern checkered plates provide directional slip resistance, commonly used in ramps and walkways.

Преимущества

-

Effective grip in a single direction

-

Clean and modern appearance

-

Good drainage along the bar direction

Disadvantages

-

Limited multi-directional slip resistance

Best Flooring Applications

-

Ramps and inclined walkways

-

Outdoor pedestrian paths

-

Loading zones

Recommended Grades: 304 / 316

How to Choose the Right Stainless Steel Checkered Plate for Flooring

When selecting a stainless steel checkered plate for flooring, consider the following factors:

1. Application Environment

-

Industrial or oily areas: Diamond pattern (5–6 mm height)

-

Food & sanitation areas: Lentil pattern (easy to clean)

-

Outdoor or coastal areas: Teardrop pattern or 316L stainless steel

2. Safety Requirements

-

High slip risk → deeper and more aggressive patterns

-

Pedestrian-heavy areas → balanced traction and comfort

3. Aesthetic Preference

-

Lentil pattern → smoother, cleaner appearance

-

Diamond pattern → rugged, industrial look

4. Load & Durability

-

Heavy equipment or traffic → thicker plates (3–6 mm)

-

Light foot traffic → thinner plates acceptable

Recommended Pattern Selection by Scenario

| Application Scenario | Recommended Pattern | Марка стали |

|---|---|---|

| General industrial floor | Diamond pattern (4–5 mm) | 304 / 316 |

| Heavy-duty factory floor | Diamond pattern (5–6 mm) | 316 |

| Commercial & public areas | Lentil pattern | 304 / 316L |

| Outdoor walkways | Teardrop / Linear bars | 316 / 316L |

| Ramps & slopes | Linear pattern (2–5 bars) | 304 / 316 |

Заключение

There is no single “best” stainless steel checkered plate pattern for flooring. The ideal choice depends on environment, safety level, hygiene requirements, and visual preference.

-

Diamond pattern delivers maximum anti-slip performance for industrial use

-

Lentil pattern balances safety and cleanliness for public and food-related spaces

-

Teardrop and linear patterns are ideal for outdoor and directional applications

By matching the right pattern with the correct stainless steel grade and thickness, you can achieve long-term safety, durability, and cost efficiency in any flooring project.