Standard: GB, AISI, ASTM, DIN, EN, JIS, SUS, etc

Certification: SGS, ISO, ROHS

Grade: 201, 430, 304, 316, or customized

Technical Treatment: Cold Rolled, Hot Rolled

Shape: Equal and unequal angle

Thickness: 0.8-25mm or customized as required

Length: 1-12m or customized as required

Width: 25mm*25mm-200mm*125mm, 50mm*37mm-400mm*104mm or customized as required

Surface Finish: Annealed & Pickled, Bright, Polished, HL, Black

Packing: Industry standard packaging or according to client’s requirement

| Parameter | Details |

|---|---|

| Standard | GB, AISI, ASTM, DIN, EN, JIS, SUS, etc |

| Certification | SGS, ISO, ROHS |

| Grade | 201, 304, 316, 430, or customized |

| Technical Treatment | Cold Rolled, Hot Rolled |

| Manufacturer | Tisco steel, Posco steel, Bao steel, etc |

| Shape | Equal and unequal angle |

| Thickness | 0.8-25mm or customized as required |

| Length | 1-12m or customized as required |

| Width | 25mm*25mm-200mm*125mm, 50mm*37mm-400mm*104mm or customized as required |

| Surface Finish | Annealed & Pickled, Bright, Polished, HL, Black |

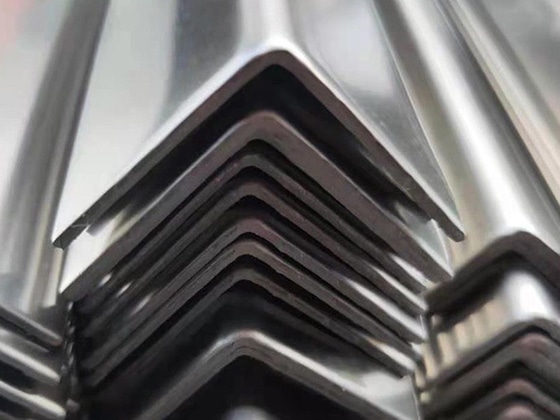

Stainless steel angles are essential structural components with a 90° L-shape profile that provides strength in both vertical and horizontal directions. Available in equal and unequal leg types, they offer engineers design flexibility based on structural needs.

Made from durable grades like 304/L, 316/L, and even Duplex or Nickel alloys, these angles provide excellent corrosion resistance, high strength-to-weight ratio, and long-term durability in harsh environments.

Lightweight yet strong, stainless steel angles are easy to fabricate, transport, and install, making them ideal for construction, framing, machinery, and architectural finishes.

Depending on application and appearance needs, stainless steel angles are produced by laser fusion, hot rolling, or cold drawing:

-

Laser fused angles offer sharp edges, precise dimensions, and large size customization—ideal for high-end architecture and tight-fitting installations.

-

Hot rolled angles are economical and strong, suited for structural framing and general support.

-

Cold drawn angles feature crisp square corners, perfect for interior decoration and trim applications.

With low maintenance needs and strong resistance to corrosion, stainless steel angles ensure a long service life, reduced replacement costs, and enhanced structural integrity.

-

Construction & Infrastructure

Used as structural supports in buildings, bridges, towers, and other load-bearing frameworks due to its strength and corrosion resistance. -

Industrial Fabrication

Applied in machine frames, support brackets, conveyors, and welding structures across manufacturing and engineering sectors. -

Shipbuilding & Marine Structures

Ideal for harsh marine environments thanks to its excellent resistance to saltwater corrosion and structural stability. -

Automotive & Transport

Utilized in vehicle frames, trailers, and transport racks requiring both durability and lightweight properties. -

Furniture & Interior Design

Serves as a framing or decorative element in industrial-style furniture, shelving systems, and architectural features. -

Electrical & Utility Support

Functions as a support component for cable trays, pipe systems, and electrical installations in commercial and industrial settings.

| Comparison Items | 200 Series (201) | 300 Series (304 as a representative) | 400 Series (430 as a representative) |

|---|---|---|---|

| Chemical Composition | Chromium (Cr) 16% – 18%, manganese (Mn) 5.5% – 7.5%, nickel (Ni) 3.5% – 5.5%, nitrogen (N) ≤0.25% | Chromium (Cr) 18% – 20%, nickel (Ni) 8% – 10.5%, low carbon | Chromium (Cr) 16% – 18%, low carbon, ferrite structure |

| Tensile Strength (MPa) | ≥520 | ≥515 | ≥450 |

| Elongation (%) | ≥40 | ≥40 | ≥22 |

| Corrosion Resistance | Moderate corrosion resistance, suitable for less corrosive environments. Prone to rusting in humid or corrosive conditions compared to 300 series. | Good general corrosion resistance, suitable for general atmosphere, fresh water and other environments, relatively weak tolerance to chloride ions | Fair corrosion resistance, better than carbon steel but inferior to 300 series. Susceptible to pitting corrosion in chloride-rich environments. |

| Magnetic Properties | Weakly magnetic due to its alloy composition | Non-magnetic in the annealed state, may become slightly magnetic under certain processing conditions | Magnetic |

| Cost | Relatively low, due to lower nickel content and relatively simple composition | Moderate, as a widely used and reliable grade | Relatively low, similar to 200 series in terms of cost, but with different performance characteristics |

| Application Fields | Interior decoration, low-end kitchenware, some decorative trims in buildings where corrosion resistance requirements are not high | Kitchen utensils, building decoration, general industrial components and other daily fields | Appliance housings, automotive trim, some food processing equipment where non-magnetic properties are not required and moderate corrosion resistance suffices |