201 vs 304 Stainless Steel

201 vs 304 Stainless Steel: Key Differences, Properties & How to Identify Them

Stainless steel comes in many grades, but 201 stainless steel and 304 stainless steel are among the most commonly used worldwide.

Although both grades are widely applied in daily life and industrial manufacturing, many buyers and engineers still ask:

What is the real difference between 201 and 304 stainless steel, and how can they be accurately identified?

As a professional stainless steel manufacturer with over 15 years of production and export experience, we explain the technical differences, chemical composition, mechanical performance, and practical identification methods of 201 vs 304 stainless steel to help international buyers make the right material choice.

Related Products:

304 Stainless Steel Sheet 304 Stainless Steel Coil Stainless Steel Strip 201 Stainless Steel Sheet 201 Stainless Steel Coil Seamless Stainless Steel Pipe Stainless Steel Welded Pipe Stainless Steel Angle Stainless Steel Flat Bar Stainless Steel Round Bars Hairline Stainless Steel Sheet Decorative Stainless Steel Pipes Stainless Steel Circle

What Is 201 Stainless Steel?

201 stainless steel is an austenitic stainless steel grade containing chromium, low nickel, and higher manganese.

It was developed in the 1930s as a cost-effective alternative to traditional nickel-rich stainless steels.

Key Characteristics of 201 Stainless Steel:

-

Lower nickel content, higher manganese

-

More competitive price than 304 stainless steel

-

Moderate corrosion resistance

-

Good formability and workability

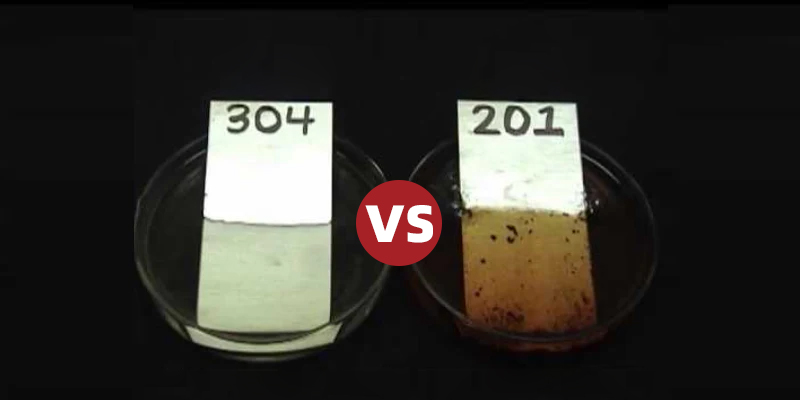

Compared with 304, 201 stainless steel has weaker corrosion resistance, especially in humid, coastal, or chemical environments.

However, it still performs well under dry indoor conditions and mild atmospheric exposure, making it suitable for:

-

Decorative stainless steel sheets

-

Kitchenware and cookware

-

Automotive trim parts

-

Furniture and household appliances

For cost-sensitive projects, 201 stainless steel is often chosen to balance performance and budget.

What Is 304 Stainless Steel?

304 stainless steel, also known as 18-8 stainless steel, contains approximately 18% chromium and 8% nickel.

It is the most widely used stainless steel grade globally and belongs to the austenitic stainless steel family.

Key Characteristics of 304 Stainless Steel:

-

Excellent corrosion and oxidation resistance

-

Higher nickel content for long-term durability

-

Very good formability and weldability

-

Suitable for food-grade and chemical applications

304 stainless steel performs exceptionally well in:

-

Food processing equipment

-

Chemical and pharmaceutical industries

-

Architectural and structural applications

-

Marine-adjacent and humid environments

In the annealed condition, 304 stainless steel is non-magnetic, though it may show slight magnetism after cold working.

Chemical Composition: 201 vs 304 Stainless Steel

Chemical composition (wt%) according to ASTM A240 / ASME SA240:

| Element | 201 | 304 |

|---|---|---|

| Carbon | ≤ 0.15 | ≤ 0.07 |

| Chromium | 16.0 – 18.0 | 17.5 – 19.5 |

| Nickel | 3.5 – 5.5 | 8.0 – 10.5 |

| Manganese | 5.50 – 7.50 | ≤ 2.00 |

| Silicon | ≤ 1.00 | ≤ 0.75 |

| Nitrogen | ≤ 0.25 | ≤ 0.10 |

| Phosphorus | ≤ 0.060 | ≤ 0.045 |

| Sulfur | ≤ 0.030 | ≤ 0.030 |

Mechanical Properties: 201 vs 304 Stainless Steel

Mechanical properties for annealed products (ASTM A240):

| Property | 201 | 304 |

|---|---|---|

| Yield Strength (min, ksi) | 45 | 30 |

| Tensile Strength (min, ksi) | 95 | 75 |

| Elongation (%) | 40 | 40 |

| Hardness (max, Rb) | 100 | 92 |

Key takeaway for buyers:

-

201 stainless steel is stronger and harder

-

304 stainless steel offers better toughness and corrosion resistance

Physical Properties: 201 vs 304 Stainless Steel

| Property | 201 | 304 |

|---|---|---|

| Density (lb/in³) | 0.283 | 0.285 |

| Modulus of Elasticity (psi) | 28.6 × 10⁶ | 28 × 10⁶ |

| Thermal Expansion (68–212°F) | 9.2 × 10⁻⁶ | 9.2 × 10⁻⁶ |

| Thermal Conductivity | 9.4 | 9.4 |

| Electrical Resistivity | 27.0 | 28.3 |

6 Practical Methods to Identify 201 vs 304 Stainless Steel

1. Chemical Analysis (Most Accurate)

-

XRF Spectrometer: Portable XRF analyzers can precisely detect nickel, chromium, and manganese levels.

-

Chemical Spot Test: Nickel test solutions react more clearly with 304 stainless steel due to its higher nickel content.

2. Magnetic Test

-

Both grades are non-magnetic when annealed

-

After cold working:

-

201 may show slight magnetism

-

304 remains mostly non-magnetic

-

Note: Magnetic testing is an auxiliary judgment, not an absolute standard.

3. Visual Appearance

-

201 stainless steel may appear slightly darker

-

Surface finish alone is not a reliable identification method

4. Price Comparison

-

201 stainless steel is significantly cheaper

-

Large price differences usually indicate lower nickel content

5. Mechanical Testing

-

201 stainless steel shows higher hardness and strength

-

Useful in laboratory or factory inspection scenarios

6. Heat & Oxidation Resistance

-

304 stainless steel offers better oxidation resistance at high temperatures

-

201 is more prone to discoloration under heat exposure

Conclusion: Which Stainless Steel Should You Choose?

When comparing 201 vs 304 stainless steel, the key difference lies in nickel content, corrosion resistance, cost, and application environment.

-

Choose 201 stainless steel for:

-

Decorative use

-

Indoor applications

-

Cost-sensitive projects

-

-

Choose 304 stainless steel for:

-

Outdoor or humid environments

-

Food-grade or chemical use

-

Long-term durability requirements

-

By combining chemical composition, mechanical properties, price analysis, and testing methods, buyers can reliably distinguish between 201 and 304 stainless steel and select the most suitable grade for their project.