Standard: GB, AISI, ASTM, DIN, EN, JIS, SUS, etc

Certification: ISO, SGS, BV

Grade: 201, 430, 304, 316, or customized

Technical Treatment: Hot Rolled,Cold Rolled,Cold Drawn,Forged

Shape: Round, Square, Flat, Hexagonal

Size: Customized

Length: 2~6m or customized as required

Surface Finish: Primary, Bright Polished

Packing: Wooden Pallet or according to customer’s requirements

| Parameter | Details |

|---|---|

| Standard | GB, AISI, ASTM, DIN, EN, JIS, SUS, etc |

| Certification | ISO, SGS, BV |

| Grade | 201, 304, 316, 430, or customized |

| Technical Treatment | Hot Rolled,Cold Rolled,Cold Drawn,Forged |

| Size | Customized |

| Length | 2~6m or customized as required |

| Surface Finish | Primary, Bright Polished |

| Application | Interior/Exterior decoration; Architectur; Evevator; Kitchen; Ceiling; Cabinet; Advertising nameplate; Roof structure;Shipbuilding |

| Processing Service | Cutting |

| MOQ | 1 Ton |

| Package | Wooden Pallet or according to customer’s requirements |

| Container Size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High); 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High); 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) |

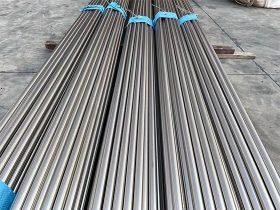

Stainless steel round bars are renowned for their hardness, tensile strength, and excellent wear resistance. They are widely used in manufacturing medium to large-sized industrial components. In structural applications, stainless steel round bars serve as reliable frameworks, bracing rods, supports, and shafts. Thanks to their ability to withstand harsh environments—including high-acid concentrations, chloride exposure, and alkaline solutions—they are a core material in producing stainless steel equipment, flanges, bolts, fasteners, and precision components.

At Orinox Steel, we offer a full range of stainless steel round bars in various grades, sizes, and specifications to meet diverse project and construction needs.

Corrosion Resistance

Compared to carbon steel bars, stainless steel round bars offer superior resistance to corrosion, making them ideal for environments with high chemical exposure. From coastal areas to chemical plants and research laboratories, they maintain their integrity without rust or surface degradation—significantly reducing maintenance and replacement costs.

High Strength

Composed of iron, chromium, nickel, manganese, and carbon alloys, stainless steel bars are engineered for high impact resistance and load-bearing performance. Their exceptional mechanical properties make them suitable for heavy-duty structures and applications requiring long-term reliability.

Excellent Hardness

With high surface hardness, stainless steel round bars resist dents, scratches, and abrasive wear. This feature supports precision fabrication, bending, and machining. Specific types like Precipitation Hardening and Martensitic stainless steel provide industry-grade hardness for use in heavy machinery and tooling environments.

Cold-Resistance Stability

Stainless steel round bars perform well under sub-zero conditions. Even in freezing environments, they retain their original shape and mechanical properties, ensuring structural stability in cold storage facilities, arctic infrastructure, and cryogenic applications.

Stainless steel round bars are indispensable in heavy industrial applications, serving as a core material in fabrication and manufacturing processes. Their corrosion resistance, high strength, non-rusting nature, and excellent hardness make them ideal across multiple sectors:

Mechanical Engineering & Fabrication

Thanks to their strength and ductility, stainless steel round bars are widely used in mechanical engineering. The equipment and machinery in this industry often operate in chemically aggressive environments, making stainless steel the optimal choice for components exposed to corrosive agents.

-

Industrial machinery parts

-

Machine frames and shafts

-

Screw components

Construction & Infrastructure

Beyond fabrication, stainless steel round bars play a key role in the construction sector. Their corrosion resistance, magnetic neutrality, and easy formability make them a durable and flexible option for architectural and structural elements.

-

Structural beams and reinforcements

-

Stainless steel gates and railings

-

Decorative and load-bearing stair components

Whether used in industrial machinery or modern architectural projects, Orinox Steel’s stainless steel round bars offer reliable performance and long service life even under the most demanding conditions.

| Comparison Items | 200 Series (201) | 300 Series (304 as a representative) | 400 Series (430 as a representative) |

|---|---|---|---|

| Chemical Composition | Chromium (Cr) 16% – 18%, manganese (Mn) 5.5% – 7.5%, nickel (Ni) 3.5% – 5.5%, nitrogen (N) ≤0.25% | Chromium (Cr) 18% – 20%, nickel (Ni) 8% – 10.5%, low carbon | Chromium (Cr) 16% – 18%, low carbon, ferrite structure |

| Tensile Strength (MPa) | ≥520 | ≥515 | ≥450 |

| Elongation (%) | ≥40 | ≥40 | ≥22 |

| Corrosion Resistance | Moderate corrosion resistance, suitable for less corrosive environments. Prone to rusting in humid or corrosive conditions compared to 300 series. | Good general corrosion resistance, suitable for general atmosphere, fresh water and other environments, relatively weak tolerance to chloride ions | Fair corrosion resistance, better than carbon steel but inferior to 300 series. Susceptible to pitting corrosion in chloride-rich environments. |

| Magnetic Properties | Weakly magnetic due to its alloy composition | Non-magnetic in the annealed state, may become slightly magnetic under certain processing conditions | Magnetic |

| Cost | Relatively low, due to lower nickel content and relatively simple composition | Moderate, as a widely used and reliable grade | Relatively low, similar to 200 series in terms of cost, but with different performance characteristics |

| Application Fields | Interior decoration, low-end kitchenware, some decorative trims in buildings where corrosion resistance requirements are not high | Kitchen utensils, building decoration, general industrial components and other daily fields | Appliance housings, automotive trim, some food processing equipment where non-magnetic properties are not required and moderate corrosion resistance suffices |