Standard: ASTM,AISI,SUS,JIS,EN,DIN,BS,GB

Material Grade: 201,304,316,430,or as required

Certification: ISO, CE

Welding Line Type: ERW/Seamless

Tolerance: ±1%

Processing Service: Bending, Welding, Punching, Cutting

Section Shape: Round

Surface: Satin / bright

Polish: Outer Polish

Packing: Standard seaworthy package(wooden boxes package,pvc package,and other package)

| Parameter | Details |

|---|---|

| Type | As Welded, EFW, ERW, Seamless, Semi Seamless, Bead Removed |

| Surface Finish | Polishing / Hairline / Colored etc |

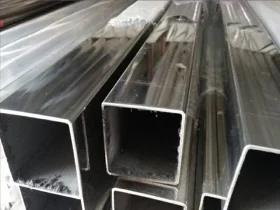

| Classification | Round Tube : OD = 8~406.4mm ; T = 0.4~12mmSquare Tube : OD = 4*4~150*150mm ; T = 0.4~6.0mmRectangular Tube : OD = 10*20~100*200mm ; T = 0.4~6.0mmOval Tube : OD = 10*20~125*300mm ; T = 0.4~6.0mm |

| Material Grade | 201,304,316,430,or as required |

| Thickness | 0.6 mm – 3 mm |

| Tolerance | ±1% |

| Length | 4000mm,5800mm,6000mm,or as required |

| Packing | Standard seaworthy package(wooden boxes package,pvc package,and other package) |

Decorative stainless steel pipe offer an exceptional blend of aesthetics, durability, and versatility, making them the preferred choice for modern architectural and interior design projects. Engineered from premium stainless steel grades such as 304/304L and 316/316L, these pipes deliver superior corrosion resistance, ensuring lasting performance even in harsh environments such as coastal areas or chemically aggressive settings.

Superior Corrosion Resistance

Thanks to their high chromium and molybdenum content, decorative stainless steel pipe form a robust, self-healing oxide layer that effectively protects against rust, pitting, and corrosion. This makes them suitable for both indoor and outdoor applications where exposure to moisture, pollutants, or salt spray is inevitable.

Elegant and Customizable Finishes

Available in a wide variety of surface treatments — including brushed (hairline), mirror polish, and PVD color coating — these pipes allow designers and architects to realize their creative visions. The finishes not only enhance the visual appeal but also improve wear resistance and ease of maintenance, providing a balance of beauty and practicality.

High Strength-to-Weight Ratio

Decorative stainless steel pipe combine impressive mechanical strength with relatively low weight, facilitating easier handling and installation without compromising structural integrity. This characteristic is essential for applications in furniture design, handrails, partitions, and façade elements where both form and function are critical.

Seamless Integration with Other Materials

These pipes complement a broad range of construction materials such as wood, glass, concrete, and stone, enabling versatile use in diverse design styles — from minimalist modern to classic elegance. This compatibility enhances the overall architectural coherence and visual harmony of the project.

Eco-Friendly and Sustainable

Manufactured from 100% recyclable stainless steel, decorative pipes support environmentally responsible construction practices. Their durability reduces the need for replacement and maintenance, contributing to a lower carbon footprint over the product lifecycle.

Low Maintenance and Long-Lasting

The corrosion-resistant properties combined with resilient surface finishes ensure that decorative stainless steel pipe maintain their shine and structural soundness over years of use, even in high-traffic or exposed areas. Routine cleaning is simple and minimal, making them highly cost-effective in the long term.

Wide Range of Specifications

Offered in various diameters, wall thicknesses, and lengths, decorative stainless steel pipe can be custom fabricated to meet specific project requirements. Whether for sleek interior accents or robust exterior cladding, Orinoxsteel provides flexible solutions that align with your design and performance needs.

| Comparison Items | 200 Series (201) | 300 Series (304 as a representative) | 400 Series (430 as a representative) |

|---|---|---|---|

| Chemical Composition | Chromium (Cr) 16% – 18%, manganese (Mn) 5.5% – 7.5%, nickel (Ni) 3.5% – 5.5%, nitrogen (N) ≤0.25% | Chromium (Cr) 18% – 20%, nickel (Ni) 8% – 10.5%, low carbon | Chromium (Cr) 16% – 18%, low carbon, ferrite structure |

| Tensile Strength (MPa) | ≥520 | ≥515 | ≥450 |

| Elongation (%) | ≥40 | ≥40 | ≥22 |

| Corrosion Resistance | Moderate corrosion resistance, suitable for less corrosive environments. Prone to rusting in humid or corrosive conditions compared to 300 series. | Good general corrosion resistance, suitable for general atmosphere, fresh water and other environments, relatively weak tolerance to chloride ions | Fair corrosion resistance, better than carbon steel but inferior to 300 series. Susceptible to pitting corrosion in chloride-rich environments. |

| Magnetic Properties | Weakly magnetic due to its alloy composition | Non-magnetic in the annealed state, may become slightly magnetic under certain processing conditions | Magnetic |

| Cost | Relatively low, due to lower nickel content and relatively simple composition | Moderate, as a widely used and reliable grade | Relatively low, similar to 200 series in terms of cost, but with different performance characteristics |

| Application Fields | Interior decoration, low-end kitchenware, some decorative trims in buildings where corrosion resistance requirements are not high | Kitchen utensils, building decoration, general industrial components and other daily fields | Appliance housings, automotive trim, some food processing equipment where non-magnetic properties are not required and moderate corrosion resistance suffices |