Standard: ASTM,AISI,SUS,JIS,EN,DIN,BS,GB

Material Grade: 201,304,316,430,or as required

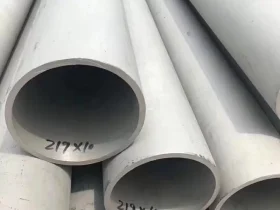

Type: Seamless

Welding Line Type: Seamless

Tolerance: ±1%

Thickness: 1mm-150mm ect.

OD: 6mm-2500mm ect.

Length: 4000mm,5800mm,6000mm,12000mm,or as required

Packing: Standard seaworthy package(wooden boxes package,pvc package,and other package)

Advantages of Seamless Stainless Steel pipe

-

The main perceived advantage of seamless stainless steel pipes is that they don’t have a weld seam.

-

Seamless stainless steel pipes provide peace of mind. Although there should be no issues with the seams of welded pipes supplied by reputable manufacturers, seamless pipes prevent any possibility of a weak seam.

-

Seamless stainless steel pipes have better ovality or roundness, than welded pipes.

| Parameter | Details |

|---|---|

| Shapes | Stainless Steel Rectangle Tube, Stainless Steel Round Seamless Tube, Square Stainless Steel Seamless Tube, Seamless U Tube, etc. |

| Thickness Range | 1mm-150mm ect |

| OD | 6mm-2500mm ect |

| Material Grade | 201,304,316,430,or as required |

| Manufacturer | Tisco steel, Posco steel, Bao steel, etc |

| Tolerance | ±1% |

| Length | 4000mm,5800mm,6000mm,12000mm,or as required |

| Packing | Standard seaworthy package(wooden boxes package,pvc package,and other package) |

1. No Welds – Superior Structural Integrity

Seamless stainless steel pipes are manufactured through a hot extrusion or cold-drawing process, resulting in pipes with no welded seams. This eliminates weak points, ensuring consistent strength and reducing the risk of leakage or failure under high pressure.

2. High Corrosion Resistance

Made from premium stainless steel grades such as 304, 316L, and 310S, these pipes offer excellent resistance to corrosion from acids, alkalis, and chlorides, making them suitable for harsh environments like chemical processing plants, offshore facilities, and marine applications.

3. Excellent Pressure and Temperature Tolerance

Seamless pipes are capable of withstanding high pressure and extreme temperature fluctuations without deformation or cracking. They are widely used in high-demand systems including steam pipelines, heat exchangers, and pressure vessels.

4. Smooth Internal Surface – Efficient Flow

With no weld bead or internal roughness, seamless pipes provide a smooth internal bore, reducing flow resistance and preventing material buildup. This feature is critical in sanitary applications, fluid transfer lines, and precision instrumentation.

5. Tight Dimensional Tolerances

Seamless stainless steel pipes are known for their precise outer diameter, wall thickness, and roundness, allowing for reliable fittings, minimal tolerance errors, and consistent performance in automated production lines.

6. Long Service Life with Low Maintenance

Due to their robust construction and anti-corrosive properties, stainless steel seamless pipes require minimal maintenance and offer an extended service life — delivering cost-effectiveness over the long term.

7. Versatile Applications

From oil & gas and petrochemical pipelines to food-grade fluid transport and pharmaceutical processing, stainless steel seamless pipes are trusted for both industrial and hygienic applications where reliability is paramount.

| Comparison Items | 200 Series (201) | 300 Series (304 as a representative) | 400 Series (430 as a representative) |

|---|---|---|---|

| Chemical Composition | Chromium (Cr) 16% – 18%, manganese (Mn) 5.5% – 7.5%, nickel (Ni) 3.5% – 5.5%, nitrogen (N) ≤0.25% | Chromium (Cr) 18% – 20%, nickel (Ni) 8% – 10.5%, low carbon | Chromium (Cr) 16% – 18%, low carbon, ferrite structure |

| Tensile Strength (MPa) | ≥520 | ≥515 | ≥450 |

| Elongation (%) | ≥40 | ≥40 | ≥22 |

| Corrosion Resistance | Moderate corrosion resistance, suitable for less corrosive environments. Prone to rusting in humid or corrosive conditions compared to 300 series. | Good general corrosion resistance, suitable for general atmosphere, fresh water and other environments, relatively weak tolerance to chloride ions | Fair corrosion resistance, better than carbon steel but inferior to 300 series. Susceptible to pitting corrosion in chloride-rich environments. |

| Magnetic Properties | Weakly magnetic due to its alloy composition | Non-magnetic in the annealed state, may become slightly magnetic under certain processing conditions | Magnetic |

| Cost | Relatively low, due to lower nickel content and relatively simple composition | Moderate, as a widely used and reliable grade | Relatively low, similar to 200 series in terms of cost, but with different performance characteristics |

| Application Fields | Interior decoration, low-end kitchenware, some decorative trims in buildings where corrosion resistance requirements are not high | Kitchen utensils, building decoration, general industrial components and other daily fields | Appliance housings, automotive trim, some food processing equipment where non-magnetic properties are not required and moderate corrosion resistance suffices |