Standard: ASTM,AISI,SUS,JIS,EN,DIN,BS,GB

Material Grade: 201,304,316,430,or as required

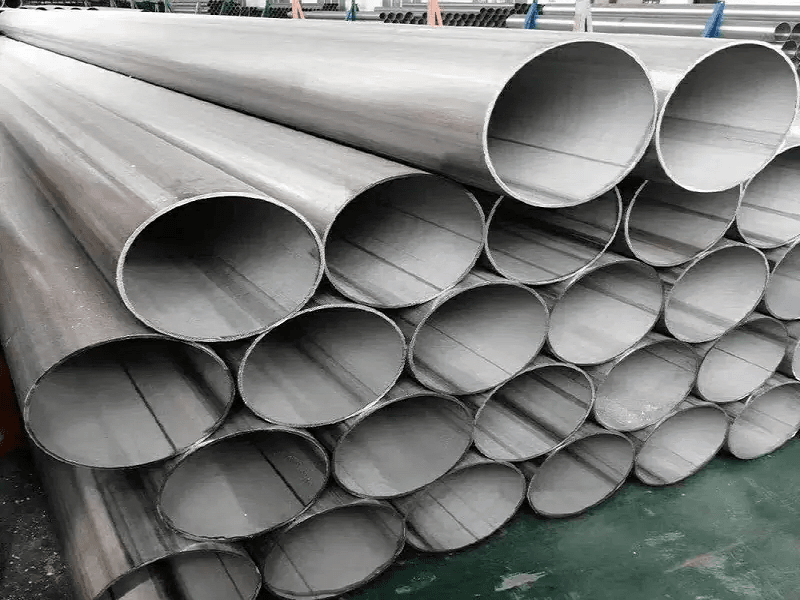

Type: Welded

Welding Line Type: Straight on

Tolerance: ±1%

Thickness: 1mm-150mm ect.

OD: 6mm-2500mm ect.

Length: 4000mm,5800mm,6000mm,12000mm,or as required

Packing: Plastic bag or customer request

Advantages of Welded Stainless Steel Pipe

-

Welded stainless steel pipe are typically more cost effective than their seamless equivalents.

-

Welded stainless steel pipe are usually more readily available than seamless. The longer lead time required for seamless pipes can not only make timing problematic, but it also allows more time for the price of the materials to fluctuate.

-

The wall thickness of welded stainless steel pipe is generally more consistent than that of seamless pipes.

-

The internal surface of welded tubes can be checked before manufacturing, which isn’t possible with seamless.

| Parameter | Details |

|---|---|

| Item | stainless steel welded pipe(stainless steel welded pipe tube, welded steel pipe, stainless steel welded pipe, stainless tube welding) |

| Thickness Range | 1mm-150mm ect |

| OD | 6mm-2500mm ect |

| Material Grade | 201,304,316,430,or as required |

| Manufacturer | Tisco steel, Posco steel, Bao steel, etc |

| Tolerance | ±1% |

| Length | 4000mm,5800mm,6000mm,12000mm,or as required |

| Packing | Plastic bag or customer request |

Welded steel pipes, also called welded pipes, are steel tubes made by welding steel or strip steel after crimping and forming. Generally, the length is 6 meters. Welded steel pipes have a simple production process, high production efficiency, many varieties and specifications, and low equipment investment, but their general strength is lower than seamless steel pipes.

-

High Corrosion Resistance

Manufactured with high-quality stainless steel grades (201, 304, 316L, 430), our welded pipes provide excellent resistance to rust, oxidation, and harsh environments — ideal for long-term outdoor and industrial use. -

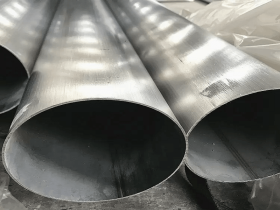

Smooth Weld Seam & Leak-Free

Precision welding technology ensures tight and clean weld seams with no leakage, suitable for pressure-bearing or fluid transport applications. -

Customizable Dimensions & Finish

Available in a wide range of outer diameters (OD), wall thicknesses, and lengths, with surface options such as 2B, BA, Mirror, HL (Hairline), PVD Color Coating, and more. -

Superior Formability & Machinability

Easily cut, bent, or fabricated to meet specific project needs — perfect for further processing or on-site installation. -

Strong Structural Integrity

High tensile strength and load-bearing performance make these pipes suitable for construction, framework, and furniture applications. -

Wide Range of Applications

Ideal for handrails, pipelines, automotive parts, industrial equipment, decorative structures, water supply systems, and furniture frames. -

Strict Quality Control

Every batch is inspected for dimensional accuracy, weld strength, surface finish, and corrosion resistance — ensuring consistent quality and compliance with international standards (ASTM, JIS, DIN).

| Comparison Items | 200 Series (201) | 300 Series (304 as a representative) | 400 Series (430 as a representative) |

|---|---|---|---|

| Chemical Composition | Chromium (Cr) 16% – 18%, manganese (Mn) 5.5% – 7.5%, nickel (Ni) 3.5% – 5.5%, nitrogen (N) ≤0.25% | Chromium (Cr) 18% – 20%, nickel (Ni) 8% – 10.5%, low carbon | Chromium (Cr) 16% – 18%, low carbon, ferrite structure |

| Tensile Strength (MPa) | ≥520 | ≥515 | ≥450 |

| Elongation (%) | ≥40 | ≥40 | ≥22 |

| Corrosion Resistance | Moderate corrosion resistance, suitable for less corrosive environments. Prone to rusting in humid or corrosive conditions compared to 300 series. | Good general corrosion resistance, suitable for general atmosphere, fresh water and other environments, relatively weak tolerance to chloride ions | Fair corrosion resistance, better than carbon steel but inferior to 300 series. Susceptible to pitting corrosion in chloride-rich environments. |

| Magnetic Properties | Weakly magnetic due to its alloy composition | Non-magnetic in the annealed state, may become slightly magnetic under certain processing conditions | Magnetic |

| Cost | Relatively low, due to lower nickel content and relatively simple composition | Moderate, as a widely used and reliable grade | Relatively low, similar to 200 series in terms of cost, but with different performance characteristics |

| Application Fields | Interior decoration, low-end kitchenware, some decorative trims in buildings where corrosion resistance requirements are not high | Kitchen utensils, building decoration, general industrial components and other daily fields | Appliance housings, automotive trim, some food processing equipment where non-magnetic properties are not required and moderate corrosion resistance suffices |